If you’ve paid much attention to the way COVID-19 affects our world, you’d know it goes just beyond an illness of the body. It’s affected the way we worship and the way we work. It’s affected how we care for and communicate with our loved ones, just to name a few. It’s also no surprise that it’s affected our economy. The UK, Japan, Germany, and the US are just a few major economies experiencing a recession due to the coronavirus.

But perhaps there is a silver lining in this pandemic after all. As many countries put their citizens in lockdown across the globe, the environment seemed to clean up a bit. CNN reported that “an international study of global carbon emissions found that daily emissions declined 17% between January and early April compared to average levels in 2019.” This change came simply from the fact that fewer people participated in road and air travel during those months.

It’s been a relatively known fact that gas-powered vehicles aren’t good for the environment, but this period of lockdown and quarantine gave us tangible data to prove it. So now that we see what happens to the earth when it’s subjected to fewer carbon emissions, what can we do to change the way we run the work truck industry to continue a downward trend of carbon emissions?

INSTALL ALTERNATIVES

An obvious way to reduce carbon emissions is to seek alternative fueling solutions for your work vehicles. Some solutions are electric-powered vehicles, fueling with propane autogas, fuel made from 100% renewable materials, hybrid vehicles, and so forth. But once you find a solution that’s just right for you, you’ll need to decide how to implement that solution. One company, Fontaine Modification, helps fleets convert their existing vehicle fuel systems to a cleaner, greener system, whether that be with complete engine installations/changes to fuel tank packages for alternative fuels.

Modern WorkTruck Solutions was able to chat with Paul Kokalis, president, and Nate Eichinger, director of operations, at Fontaine Modification to learn the ins and outs of the company’s conversion process. But let’s first share a little background.

Fontaine Modification has installed alt-fuel systems for more than a decade, beginning in 2007 and 2008 when fleets first began putting test units into operation. Back then, Fontaine Modification received a glider kit from the OEMs with a pre-installed natural gas engine. Fontaine Modification completed the conversion by adding the tanks and the fuel system. Paul and Nate say in those days, Fontaine Modification was heavily involved in alternative fuels for light-duty trucks that already had LPG engines; Fontaine Modification just added the tanks and systems.

for Staples.

STEP BY STEP

Fontaine Modification’s steps to conversion depends on the truck. Each manufacturer has a different system, and each manufacturer’s system varies depending on the truck model. Some manufacturers offer a conversion prep package, and some do not; however, even if an OEM has alternative fuel installation available, Nate and Paul say that customers contact Fontaine Modification for different tank mounting options.

Fontaine Modification’s early installation process involved removing lines, the fuel tank, injectors, and pressure regulators and replacing them with alternative fuel components. But today the process looks a little different. OEMs send trucks that don’t require as much work, eliminating unnecessary components and saving time.

Now when Fontaine Modification installs LPG engines in lighter trucks, technicians update or replace the ECU module to adjust the programming for the engine. Additionally, Fontaine Modification installs hundreds of CNG systems annually.

Fontaine Modification performs installations for most fuel system suppliers. These suppliers typically package their own systems, and Fontaine Modification ensures the system is installed and ready for work. The process involves installation of the tank system, plumbing, testing, and filling the system. Based on the complexity of the system—saddle tanks vs back of cab, for example—an installation could take 6 to 10 hours to complete.

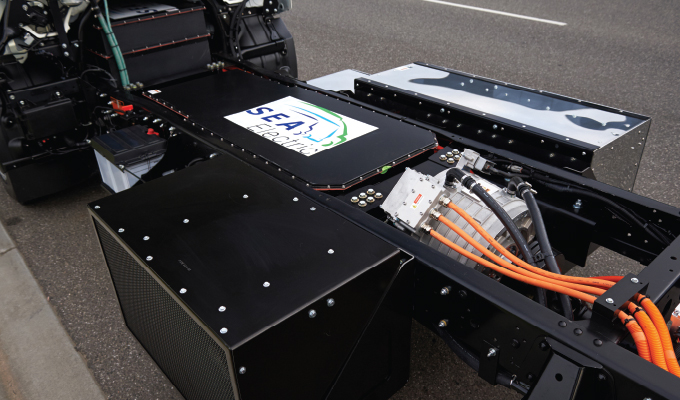

Paul and Nate share that battery drivetrains are gaining momentum in the industry, especially in light-duty, regional trucking. However, the conversion process for electric is more complex than other alternative fuels. Chassis packaging for electric systems generally requires a substantial amount of engineering work from the folks at Fontaine Modification before the truck is ready for fleet work. Nevertheless, Fontaine Modification currently has multiple electrification projects in the works for different applications, suppliers, and customers.

WHY FONTAINE?

Multiple companies perform fuel system conversions. But Nate and Paul share that a fleet manager should choose Fontaine Modification to perform their conversions for a couple of reasons. First, the company’s history in the trucking industry is long and includes extensive knowledge of alternative-fuel systems and packages. The company also works with customers to ensure they get the right components for their application.

Another perk: Fontaine Modification has ship-through agreements with all major OEMs, which means that the truck maintains its equalized freight system even after Fontaine performs the install—at no extra cost to the customer. Even if your fleet features multiple truck models from multiple OEMs, Fontaine Modification can deliver consistency because of its standardized installations and quality controls across all OEMs and installation centers.

The silver lining of COVID-19 is encouraging when it comes to improving the current state of our environment. But these lower carbon emissions numbers won’t last once lockdown regulations loosen. One way to contribute is by converting your gas- and diesel-powered fleet to sustainable, alternative fuel systems. And Fontaine Modification can help.

FOR MORE INFORMATION

Paul Kokalis is the president of Fontaine Modification Company. He has been in the industry for almost 40 years. Nate Eichinger is the director of operations at Fontaine Modification Company, beginning his career in engineering and quickly moving to a leadership role at Fontaine. Find out more, visit www.fontainemodification.com.