Link Mfg., Ltd. unveiled what will become the industry’s first family of intelligent auxiliary suspension systems. With field testing in progress, Link expects the 8K, 10K, 13.5K, and 20K ROI Auxiliary Suspensions Systems to be commercially available in 2022. Link presented the products and the technology behind them during a press conference at TMC 2021 Cleveland, Ohio.

Using a traditional auxiliary suspension system generally requires a significant amount of guesswork, even for experienced vehicle operators. Unfortunately, in an era of increasing driver shortages and diminished experience levels, human error is common. While most systems allow users to manually set deployment pressure, those auxiliary suspensions are still binary; they are either up or down.

“If an auxiliary suspension system is engaged when not needed, it can cause the tires to drag, or ‘scrub,’ negatively affecting tire wear, gas mileage, and maintenance intervals,” says Mike Leakey, vice president of sales and marketing for Link Mfg. “Conversely, if auxiliary axles are not deployed when needed, the vehicle may not comply with local bridge laws, and the vehicle and its occupants may even be exposed to dangerous mechanical forces.”

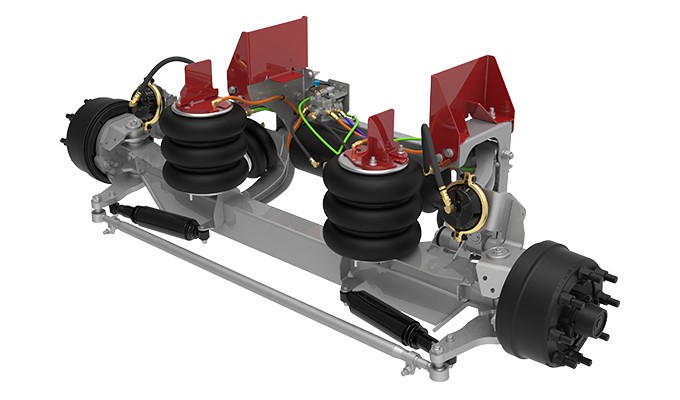

ROI AUXILIARY SUSPENSION SYSTEM

Link developed its new, smart load-balancing suspensions using its proprietary Road Optimized Innovation (ROI) technology. First introduced in the company’s ROI Cabmate Cab Suspension in 2019, the groundbreaking ROI Auxiliary Suspension System will sense and maintain optimal tire-to-ground pressure, reducing tire wear and maximizing fuel mileage. Link’s intelligent load-balancing auxiliary suspension system removes the guesswork of when to lift or lower; even inexperienced drivers can maintain maximum traction without overloading the axles.

“Link’s ROI technology is able to sense when the vehicle’s load has changed and automatically deploys or retracts the auxiliary suspension system as needed,” says Eli DeGroff, product manager, Road Optimized Innovations for Link Mfg. “Unlike traditional all-on or all-off auxiliary axles, Link’s smart suspensions are able to determine the load they need to bear and automatically adjust to precisely accommodate that weight.”

Intelligent suspensions like Link’s new auxiliary offerings automatically respond to the vehicle’s wheel traction and make manual retraction unnecessary. In challenging conditions, Link’s ROI technology, working with the vehicle’s ABS, will sense the absence of surface friction; it will then reduce pressure as needed to shift the requisite tractive force to the drive axles.

“With Link’s ROI Auxiliary Suspension System, fleets will be able to get new drivers trained and working in less time,” Leakey explains. “Exceeding axle ratings can be dangerous as well as costly due to unscheduled maintenance and fines. Now even novice drivers can avoid these issues, maintaining safety and efficiency.”

Link’s ROI load-balancing auxiliary suspension system keeps a vehicle’s drive axles loaded, keeping traction and braking at optimal performance levels. Link’s ROI technology reduces strain on frames and primary suspension components and lowers operating costs.

IN THE FIELD

Link’s intelligent auxiliary suspensions will be suitable for trucks and tractors in the heavy-duty, on-highway and off-highway arena. This includes dump bodies, cement trucks, roll-off trucks, and other vocational applications. For its initial aftermarket product launch, Link will design a Bodybuilder Package with the control system integrated into the suspension. Link’s Swift Mount technology with its Bodybuilder Package will allow intelligent auxiliary axle installs in less time than traditional installations.

“Using Link suspensions with ROI technology, fleets and independent owner-operators can expect superior handling, better fuel mileage, reduced tire wear, more uptime, and a lower overall cost of ownership,” Leakey says.

Find out more, visit www.linkmfg.com.