How can an engine manufacturer ensure it remains relevant for years to come—especially in an industry that’s rapidly moving toward alternative fuels? Well, just ask Cummins.

The engine manufacturer announced back in February it will expand its powertrain platforms to leverage a range of fuel types. Cummins will achieve this by designing fuel-agnostic engines. The engines will all use the same platform with engine blocks and core components that share common architectures and optimized for different fuels.

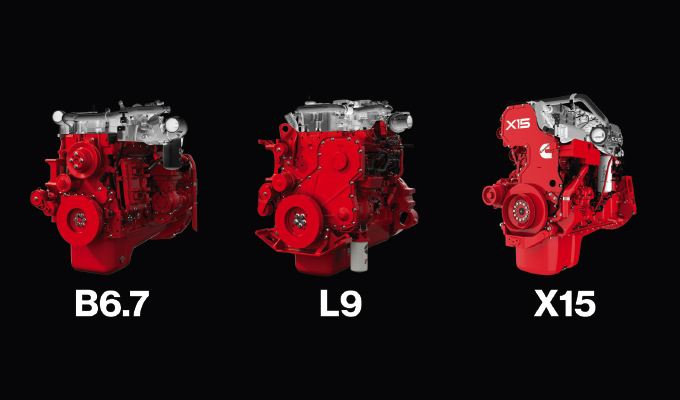

Cummins’ plan is to apply this new design across its B, L, and X-Series engine portfolios, which will be available for diesel, natural gas, gasoline, and in the future, hydrogen.

HOW IT WORKS

Cummins is well on its way to making history by creating the industry’s first fuel-agnostic engines. But how exactly will it work in the field?

These new fuel-agnostic engine platforms will feature a series of engine versions derived from a common base engine. This means the engines will have a high degree of parts commonality. Below the head gasket of each engine will largely have similar components, and above the head gasket will have different components to accommodate the different fuel types. It’s important to note that the head gasket components are not interchangeable. The engine version ordered will operate using only the single fuel type for which it was intended.

AGNOSTIC BENEFITS

Parts commonality among engines with different fuel types has its benefits for both truck OEMs and end users. This includes similar engine footprints, diagnoses, and service intervals. Therefore, it will be easier for OEMs to integrate a variety of fuel types across the same truck chassis. This means fleet owners can choose the fuel type that makes the most sense for them, even if that means using one type of fuel in one truck and another type of fuel in the same kind of truck being used in a different location.

“Having a variety of lower carbon options is particularly important considering the variation in duty cycles and operating environments across the many markets we serve,” says Srikanth Padmanabhan, president, Cummins Engine Business. “There is no single solution or ‘magic bullet’ that will work for all application types or all end users.”

Aside from fuel variety, having parts commonality benefits service technicians and service locations. With the Cummins fuel-agnostic engine, there will be minimal costs to train technicians and re-tool service locations, resulting in a lower total cost of ownership for the end user. These fuel-agnostic engines present a “common-as-possible” solution from a technician and service standpoint, and the unified products will look and feel similar to technicians—after all, the engines will all use the same parts and components with just a few modifications.

FOR EVERY FLEET

It’s natural to feel a little uneasy about something this revolutionary. But Jonathon White, vice president of engineering, Cummins Engine Business, says that Cummins’ customers can be confident in its unmatched testing and evaluation process, which ensures high-performance products.

And Cummins will use its full range of testing and evaluation to produce the fuel-agnostic engines, as well. Cummins will design and build these fuel-agnostic platforms upon the learnings the company has extracted from millions of diesel and natural gas engines manufactured and currently in use. Today’s digital and connected technologies allow Cummins to extract insights specific to different engine duty cycles and leverage these to design reliable fuel-agnostic platforms.

These insights, tests, and evaluations will help Cummins design a fuel-agnostic engine that delivers diesel-like performance on a fuel that produces fewer carbon emissions. Additionally, real fleets will test and evaluate the fuel-agnostic products to even further offer peace of mind that the fuel-agnostic engines are just as reliable, powerful, and dependable as the Cummins engines fleet owners and technicians already know and love. Best of all, these engine options ensure Cummins has a powerful solution for any fleet in any application—even fleets in states that have adopted California Air Resources Board (CARB) emissions standards.

White says the fuel-agnostic engine presents a new way to design and develop lower emission internal combustion powertrains that meet the needs of each and every fleet, allowing users to “more seamlessly pick the right powertrain for their application with the lowest CO2 impact.”

FOR THE PLANET

Not only does the decision to manufacture fuel-agnostic engines ensure Cummins’ future in the industry, it also contributes to Cummins’ goals. These new engines are an important element of Cummins’ strategy to go further, faster and reduce the greenhouse gas (GHG) and air quality impacts of its products to reach net-zero emissions by 2050 in a way that serves all stakeholders in a sustainable way for Cummins’ business. This commitment requires changes to Cummins’ products and the energy sources that power them.

“We know that our planet cannot wait for the perfect solution to happen,” Padmanabhan says. “Instead, our approach must be a combined effort of using zero emissions power where it’s available and using cleaner power where it is not. The planet cannot afford for us to hit pause in the meantime.”

Two of the company’s environmental sustainability goals for 2030 include reducing scope 3 absolute lifetime greenhouse gas emissions from newly sold products by 25% and partnering with customers to reduce scope 3 GHG emissions from products in the field by 55 million metric tons.

“Getting to zero is not a light-switch event,” Padmanabhan concludes. “Carbon emissions that we put into the atmosphere today will have a lasting impact. This means anything we can do to start reducing the carbon footprint today is a win for the planet. We need to take action now.”

WHAT’S TO COME

Cummins will begin to roll out these engines in 2024—although they won’t all roll out at once. On the B platform, Cummins plans to launch the gasoline engine first. On the L platform, Cummins’ plan is to launch the natural gas engine first with the diesel engine launching shortly after.

Once all the engines are launched, customers will be able to pick which fuel type makes the most sense for their fleet—and the team at Cummins feels that most fleets will find their perfect solution in a combination of fuel types to help their business make money without negatively impacting the environment.

FOR MORE INFORMATION

Find out more about Cummins’ fuel-agnostic engines, visit www.cummins.com.