Replacing just one critical truck component can be pricey. Parts and labor prices are on the rise—not to mention hard to come by—and vehicle downtime can add up quickly.

As interest rates rise, it’s important to run a tight business. Financing costs are also expected to rise, and used-truck equipment prices aren’t showing signs of slowing. The pressure on profit margins is tightening and likely will continue for the next year.

Avoiding breakdowns is the name of the game.

A Zonar customer, Hot Line Construction, a voltage utility services company, uses technology to curb the risk of major repairs. The company has a mixed fleet of 800 specialized vehicles, including pickups, cars, cranes, powered trailers, and Class 4, 5, and 6 trucks. They travel to construction sites across cities and suburbs and even remote areas with harsh environments. Fleet managers needed a remote way to monitor vehicle health. This would help them identify maintenance issues like ruptured hoses before catastrophe struck. That’s how a $40,000 alert saved the day.

Less than five miles from the yard, a low coolant alert came through. A failed EGR cooler can lead to an engine overhaul or complete replacement. But a new hose could be fixed for $30. Given supply chain stresses, major unexpected repairs—such as a new engine—were out of the question. Managers advised the driver to park immediately. Five miles wasn’t worth the risk.

PREDICT TO PREVENT

Today, many work truck fleets schedule regular inspections and repairs based on a predetermined set of miles or hours a vehicle or asset is in operation. It’s a preventive approach to maintenance, but even with the best practices in place—consistent pre- and post-trip inspections, asset-specific inspections, and good record-keeping—fleet managers still don’t have a complete picture of the real health of trucks and equipment. Just one pencil-whipped miss in a trip inspection can lead to breakdowns or accidents on the road.

But fleets can close the gaps in preventive maintenance programs with predictive technologies.

Consider if a minor problem were to arise between a routinely scheduled maintenance check. A minor defect can easily scale to a much more expensive repair, forcing vehicles out of service unexpectedly and costing more time and money.

Rather, modern predictive maintenance bases real-time fleet health on sensor data and connected assets to provide insights of each vehicle in a fleet. Telematics-enabled platforms collect diagnostics data from the brakes, engine, and transmission of every vehicle in the fleet.

This works in conjunction with verifiable, digital pre- and post-trip inspections such as Electronic Driver Vehicle Inspection Reports (eDVIR or EVIR). This digital process helps catch defects and puts drivers in a safety mindset. Drivers scan specific components on their truck to meet compliance and safety standards, creating a digital record that gets directly integrated via telematics into the fleet’s maintenance software. After all, safety is the responsibility of the full organization: drivers, management, and dispatch.

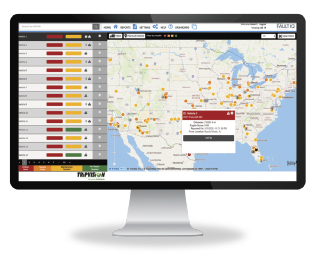

The other component of predictive programs is maintaining a constant pulse on your fleet. Physically checking each yard to investigate the fleet’s health is a major time expense. However, new systems from smart fleet management providers can provide live text and email alerts on vehicle health, safety scores, fault codes, and vehicle locations. This gives fleet managers, drivers, shop technicians, and mechanics a map view of each truck’s health in the fleet.

Now, when a fault is triggered, fleet managers review the problem and look for actionable insights into what needs to be done. An escalating fault code system shows whether drivers can safely keep going or if they should pull over at the next truck stop. By fixing small problems before they become big, companies can reduce downtime and parts replacements, keeping their vehicles and assets on the road.

A STEP AHEAD

Maintenance and downtime are taking a toll. As of August 2022, American Transportation Research Institute data shows the average truck-tractor unit drove 11% less in 2022 than the prior year—the lowest amount on record of the past decade. This may indicate that fleets were not driving as far due to more maintenance downtime with outdated parts and trucks.

Although the supply chain is stabilizing, inventory of new trucks and parts is still limited, used parts are still expensive, and operating costs are on the rise. Fleet managers have had to make do. Those who boosted preventive maintenance programs with predictive technologies were better positioned to avoid the breakdowns caused by progressive degrading.

Now, they’re not just capturing diagnostic trouble codes. Managers can analyze and determine trends, such as which make and model has specific failures and how those compare to other makes and models. As a result, telematics improves maintenance programs and helps fleet managers better plan their purchasing decisions for parts or new vehicles. That’s not just good for safety, it’s good for the bottom line.

Fleets have an opportunity to think smarter about vehicle maintenance and driver support. The safest drivers know to look far down the road. The same is true with managing operations and maintenance expenses. Preventive and predictive maintenance technology make it possible to look ahead.

ABOUT THE AUTHOR

Fred Fakkema is the vice president of safety and compliance at Zonar. Find out more, visit www.zonarsystems.com.