When people think of road safety, they typically consider how drivers operate—how fast they’re driving, tight turns, level of braking, and their concern for others. However, another component that plays a significant role in road safety is preventive maintenance on a fleet. Inspections should be conducted regularly to cover various components, including brakes, tires, suspension, lights, and more. These inspections help identify potential problems early, reducing the risk of accidents, injuries, and costly vehicle repairs in the future.

In addition to safety, regular inspections also contribute to vehicle efficiency. Maintenance and repairs can ensure vehicles run optimally, reducing fuel consumption, saving money on repairs, and increasing vehicle lifespan. Preventive maintenance programs, which include regular fleet inspections, can result in cost savings ranging from 12% to 18% in overall maintenance costs. So, fleet inspections are a regulatory requirement and a critical aspect of fleet management. By conducting regular inspections and keeping detailed records of maintenance and repairs, fleet managers can demonstrate their commitment to safety and compliance, reducing the risk of costly fines and legal issues.

The COVID-19 pandemic created significant bottlenecks in the vehicle service industry for fleet trucks and vans, including the skyrocketing fuel, parts, and labor prices, increasing the cost of operating a fleet and causing delays to ensure preventive maintenance to get vehicles back on the road. According to the American Trucking Association, vehicle parts and labor costs increased 14.4% and 10.8%, respectively, with combined expenses up 13%, and they’re expected to continue rising. Now, as the world puts the pandemic in the rearview mirror, there are still challenges fleet managers face, but regular fleet inspections are one area they can’t put a brake on.

WHY INSPECT

The adage “If it isn’t broken, don’t fix it” was not directed toward a fleet manager. As with any vehicle, commercial trucks and vans must receive regular maintenance to ensure everything is running correctly and there aren’t any possible issues that could derail a truck’s schedule and cause driver downtime. Vehicle downtime from unplanned maintenance is expensive for organizations, and unexpected repairs drain profits, especially if they occur repeatedly. Manual maintenance tracking also incurs costs in terms of labor hours spent entering and retrieving information. This involves physically recording odometer readings, conducting tests, and researching diagnostic codes.

Properly investing in preventive maintenance before an issue becomes irreversible reduces the cost and safety risks associated with a mechanical problem. It can mean the difference between having a $50 part replaced and spending $5,000 on a critical replacement later on. By leveraging the proper preventive maintenance system, fleet managers will experience reduced equipment due to breakdowns and driver downtime, reduced service and towing costs, and enhanced customer service via on-time performance. In addition, automating maintenance eliminates guesswork and manual processes, keeping a fleet up to date.

MAINTENANCE TECH

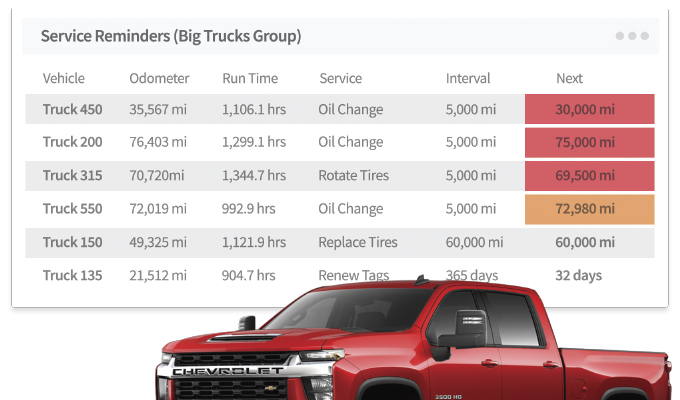

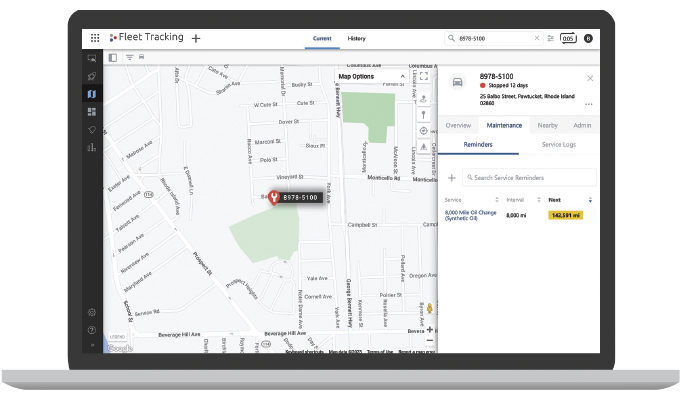

A robust tech solution alerts fleet managers of potential issues before they become costly problems. Preventive maintenance tools built into technology offer valuable vehicle data to keep operators apprised of what’s going on with the truck or van internally to avoid system failures. GPS tracking is one tool fleets have implemented to improve maintenance management. GPS tracking software automates various vehicle and asset services, such as oil changes, tire rotations, and car washes. It provides automated reminders for service due dates and maintains a digital log of service information and costs. In addition, service intervals can be set based on mileage, runtime hours, or specific dates for inspections, registrations, and warranty renewals.

GPS tracking helps manage vehicle maintenance and reduces the risk of breakdowns by improving maintenance scheduling through notifications and generating reports for upcoming or overdue maintenance. By optimizing vehicle use, GPS tracking software can extend their lifespan. It provides data on trips, usage duration, engine hours, mileage, and driver information. Implementing preventive maintenance through GPS tracking software ensures trucks operate efficiently and helps avoid unnecessary costs and risks associated with poor upkeep, keeping revenue-generating vehicles on the road and customers satisfied.

SUSTAINABILITY

Part of preventive maintenance involves ensuring fleets do their part in helping the environment. Regular fleet inspections and preventive maintenance help make sure vehicles are as up-to-date as possible before hitting the road. Staying on top of maintenance and inspections helps keep quality vehicles on the road and ensures they aren’t increasing emissions due to unmaintained parts.

Fleet management solutions offer ways to be greener by supplying fleet managers with actionable insights on reducing idle time, limiting carbon emissions, and keeping operators aligned with their sustainability goals.

SIMPLIFY & IMPROVE

Regular inspections and maintenance help identify potential problems early and contribute to optimal vehicle efficiency, resulting in fuel savings and reduced repair costs. By conducting regular inspections and keeping detailed records of maintenance and repairs, fleet managers demonstrate their commitment to safety and compliance, minimizing the risk of fines and legal issues. Automated maintenance systems, such as GPS tracking software, simplify maintenance scheduling and improve fleet management. Implementing preventive maintenance through technology reduces costs and risks and extends the lifespan of vehicles, keeping revenue-generating assets on the road. By prioritizing regular inspections and preventive maintenance, fleet managers can enhance safety, efficiency, and sustainability while optimizing operations.

ABOUT THE AUTHOR

Ray Kosick is a product manager at GPS Insight. Kosick has worked at GPS Insight on the product team since 2008. As product manager, Ray focuses on hardware, safety, and compliance, managing internal and external product communications, new product analysis, and positive team management. Find out more, visit www.gpsinsight.com.