In the work truck industry, heavy-duty work trucks like sewer cleaners are essential to getting the job done with high-pressure water jetting and a high-flow vacuum. For the municipalities and contractors that rely on these work trucks to clean endless miles of sewer lines, the goal has always been to clean more with less effort and fewer resources. Now, the goal is within reach.

Innovation in lightweight skid nozzle stabilizing attachments is enabling sewer crews to move up the line more easily than ever before, without getting caught on obstructions such as protruding taps, offsets, and deflections.

Today, advancements in skid design can substantially improve the balance and maneuverability of nozzles and hoses to speed up the sewer cleaning process. When used in conjunction with high-performance nozzles, the combination provides faster cleaning with less demand for power, pressure, and water from the truck. The approach not only eases operator workloads, but also reduces the cost of fuel, water use, and mechanical wear and tear on the vacuum truck.

STREAMLINING SEWER CLEANING

When sewer cleaning (also called sewer jetting) with a work truck, a high-pressure water hose with a specialized nozzle is placed into the line. Operators release high-pressure water from the truck to dislodge debris and flush it into a manhole. As debris is removed, the hose is pushed deeper into the sewer. Jetting typically involves using between 50-85 gallons of water per minute with a 3/4- to 1-inch hose from the truck to flush out debris lodged in the pipe. Operators may also use a vacuum to remove dislodged debris and transfer it to disposal bins.

To maintain stability with the high-volume work truck jetting, operators typically use nozzle skid attachments to keep the nozzle and hose centered within the sewer pipe. Today, some designs go far beyond this basic function and can significantly improve safety and performance.

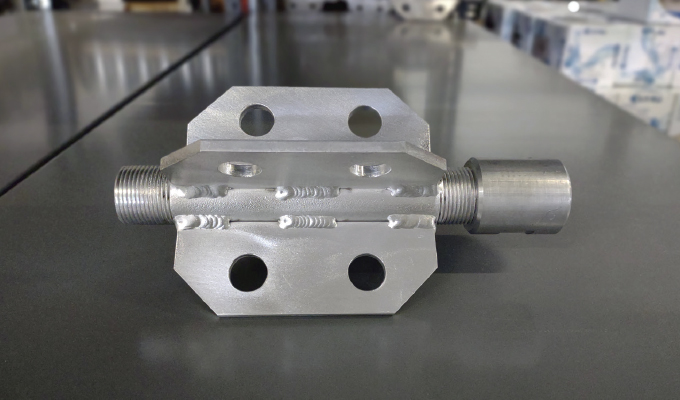

“More advanced skids with holes are designed to balance the nozzle inside the pipe and prevent the nozzle from becoming airborne and coming out of the manhole. Providing additional holes allows the user to secure the nozzle on the skid while inside the pipe,” says Dan Story, an experienced trainer and operations manager at KEG Technologies, a manufacturer of sewer and storm line products.

The challenge is that traditional skids are often constructed of steel, which adds weight and reduces maneuverability within the sewer line. In response to these challenges, Story sought to ease cleaning sewer lines. Through testing and experimentation, he discovered a specific technology that could have major implications for municipalities and contractors tasked with cleaning more lines with fewer resources.

“I discovered that if I used a high-performance aluminum nozzle with an aluminum skid, I could gain approximately 30% more power than typically available through conventional options. That meant I could lower the nozzle flow and pressure and still have all the cleaning power I had before,” shares Story.

Story has further refined the skid design after doing additional R&D and testing. The new skid design uses a lightweight aluminum pipe core with protruding plastic fins to provide nozzle stability without the weight of heavier steel skids. The skid design resembles the shape of a football to reduce the risk of snagging on sewer pipe obstructions.

“The design lowers the weight and drag of the skid and nozzle in the pipe. The lighter the weight, the easier it is to propel up the line,” says Story. “The football shape and the slick plastic fins also reduce friction, allowing the skid to pass over common sewer pipe obstructions, such as protruding taps, offsets, and deflections. If it hits a deflection in a pipe, for instance, it will ‘climb on top’ of the next step and keep on going.”

The approach enables superior sewer line cleaning with significantly less power, psi, and water, which translates into some important advantages in the field and benefits for the work truck.

BETTER CLEANING

Cleaning sewer lines at lower pressure reduces the load on vacuum trucks. Toward this end, using a lightweight aluminum skid improves nozzle maneuverability to keep the jetted water stream centered within the pipe and focused where it needs to clean.

When used with a high-performance aluminum nozzle, the combination can produce at least 30% more cleaning power than traditional options because it keeps the jetted water stream centered within the pipe and focused where it needs to clean. This reduces pressure and water use while still achieving efficient cleaning. Just as important, it allows the operator to lower the vacuum truck’s rpms, allowing them to better conserve the vehicle’s fuel use and decrease mechanical wear and tear.

“Operators can essentially run the vacuum truck at idle if they are using an aluminum skid and nozzle,” Story explains. “They do not have to crank up the truck’s rpms. Instead, they can effectively clean sewers with as little as 1,000 psi at 35 gallons a minute. It’s going to be a game changer for cities.”

To accommodate the range of sewer pipes in the field, KEG offers aluminum skids in 6-inch, 8-inch, 10-inch, and 12-inch sizes for use with aluminum Tier 3 nozzles. There are several tiers of nozzles, rated for water efficiency from Tier 1 (about 30% efficient), Tier 2 (50-60% efficient), to Tier 3 (75-98% efficient).

By more effectively containing, controlling, and directing high-pressure water with less turbulence, an aluminum Tier 3 nozzle can deliver more cleaning power at lower psi. This eliminates the need for work truck operators to compensate for the lack of power from Tier 1 or 2 nozzles by increasing the pressure to higher psi on the way back through the line. Ultimately, less psi facilitates safer, more efficient sewer cleaning that complements the use of an aluminum skid.

As municipalities and contractors seek to easily clean sewer lines with fewer resources, taking advantage of innovative aluminum skids and nozzles that enable superior cleaning at lower pressure with less water from work trucks will become a best practice strategy.

ABOUT THE AUTHOR

Del Williams is a technical writer based in Torrance, California. For more information, visit www.kegtechnologies.net.