As infrastructure projects continue to proliferate across America, work truck safety lighting has become increasingly critical. This is the story of how industry collaboration between a truck body manufacturer, a distributor and a lighting innovator resulted in an inventive solution that’s making work trucks safer and more efficient.

IT’S ALL CONNECTED

Since 1992, EWH Spectrum has been manufacturing wire harnesses for work truck manufacturers and truck modification centers from their facility in Bellefontaine, Ohio. What started as a focused operation has grown into a nationwide enterprise, shipping custom harness solutions to manufacturers and upfitters in virtually every state from California to Maine. Their sustained growth reflects the explosive expansion seen in the work truck market over the past five years – a surge that shows no signs of slowing despite some predictions.

Over three decades, they’ve built strong relationships with industry leaders like Stahl Truck Bodies and Optronics International. Their 15-year partnership with Optronics has given them unique insights into the evolution of vehicle lighting technology, particularly the trend toward consolidating multiple functions into single, efficient units.

A LIGHT WENT ON

The story of the new STLW68 Series Fusion Surface Mount LED combination stop/turn/tail/back-up/warning light began with Stahl’s recognition of the industry’s movement toward consolidated lighting functions. Having successfully implemented Optronics’ standard STL68RB combination stop, turn, tail, back-up light as standard equipment on their truck bodies, Stahl saw an opportunity to further improve that lighting system by incorporating warning light functionality into the same housing.

As Stahl’s long-time harness supplier, EWH was in a unique position to help bring this idea to fruition. When Stahl approached them about integrating warning light functionality into their existing lighting package, EWH immediately reached out to an Optronics sales representative, James Thornberry, who quickly engaged their engineering team.

FUSION REACTION

What happened next demonstrated the power of collaboration in our industry. Optronics embraced the challenge but also surprised everyone with their response. While initially estimating six months to produce a prototype, they delivered one in just three months. Production began a month later and the first units were shipped within five months of the initial request – in my experience, that is a remarkably fast timeline for developing and manufacturing a new product.

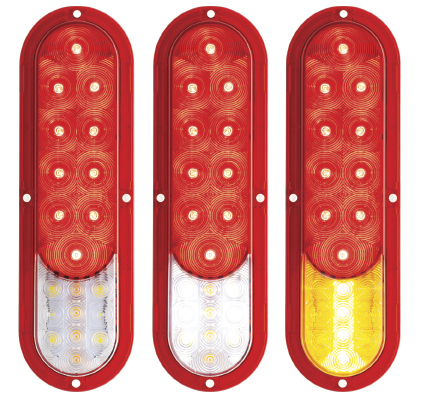

The resulting STLW68 Series Fusion surface-mount LED combination stop, turn, tail, back-up, warning light delivered what was promised. It’s a surface-mount unit that merges stop, turn, tail and backup functions with integrated warning light capabilities. The light features both amber and clear warning functions, offering more versatility than originally requested. Crucially, it also includes an intelligent priority system that automatically overrides the warning light function when brake lights are activated, ensuring constant DOT compliance, and maximizing safety.

TECHNICALLY SPEAKING

Meeting SAE J595 standards for Class 2 and Class 3 directional warning lamps, the unit is sonically sealed and waterproof. Its low-profile design protrudes just half an inch above the mounting surface, while the total depth of 0.79 inches includes a built-in circular conduit that protects the wiring – a feature that harness manufacturing experience says will significantly reduce maintenance issues.

From an engineering perspective, the STLW68 Fusion light offers key advantages. Unlike grommet-mounted lights that require large mounting holes, Fusion’s surface-mount design requires only a small wire feed-through hole, maintaining the structural integrity of the truck body while providing security against theft. The polycarbonate lens and housing ensure longevity, while the unit’s compact 10.13-inch wide, 3.04-inch-tall oval footprint allows flexible placement options.

Jake Stickney, director of engineering at Stahl, says that the light’s sealed, waterproof, multi-function capabilities, and compact envelope were crucial factors in their decision to adopt it. “The panel-mount design with its waterproof gasket ensures long-term reliability in demanding environments,” says Stickney. “Combined with its broad functionality, makes it an ideal solution for our utility bodies.”

FRINGE BENEFITS

The integration of multiple functions into a single unit delivers practical advantages. Traditional setups often require four additional warning lights on the rear of a truck, each needing separate wiring and mounting holes. STLW68 eliminates this complexity, reducing installation time, minimizing potential failure points, and maintaining the vehicle’s structural integrity. For a harness manufacturing operation, this means simpler, more reliable wiring solutions that reduce both material costs and installation time for our customers.

The development process also highlighted the value of industry partnerships. Optronics worked closely with EWH to ensure the light met Stahl’s specific requirements, including providing longer wire leads to accommodate the custom connectors. This attention to detail and willingness to customize solutions exemplifies how manufacturers, distributors and end-users can and should work together effectively in the work truck industry.

LIGHTING THE WAY

Looking ahead, this type of integrated lighting solution represents the continued progression of work truck safety lighting. Just as LED technology became the industry standard, we expect to see integrated warning light functionality become increasingly common across all manufacturers’ product lines. The efficiency and functionality benefits are simply too compelling to ignore.

This project serves as a prime example of how industry participants at all levels can work together to advance technology and improve safety in the work truck sector. When manufacturers listen to their customers and distributors effectively communicate their needs and solutions, the entire industry benefits from faster innovation and better products.

EWH Spectrum, after being granted a six-month exclusive distribution agreement for this product, highlights the value that manufacturers place on distributors who facilitate innovation. However, the real satisfaction comes from helping bring together partners to create solutions that make work trucks safer and more efficient.

The work truck market remains remarkably strong, with continued growth in infrastructure projects driving demand for innovative solutions. As we look at the future, the success of the STLW68 project demonstrates that the fusion of vision, collaboration and responsiveness to customer needs will continue to be the driving forces behind meaningful innovation in our industry.

for more information

To learn more about Optronics’ STLW68 Series Fusion Light, visit www.optronicsinc.com.