When it comes to tires, improper inflation can lead to reduced fuel efficiency, increased costs, and safety risks. But, properly maintaining optimal tire pressure can be a grueling maintenance challenge for fleet managers. Tire pressure optimization technology presents an opportunity to offer a comprehensive, smart solution for the commercial vehicle industry.

A variety of factors causes tire pressure changes, from nails or tacks stuck in the tread to overtightening of valve cores and leaking valve stems. Losing just a few pounds per square inch (psi) may not seem like a concern, but these losses over time can lead to trouble—especially when the problem isn’t noticed right away.

DANGERS OF UNDERINFLATION

According to a report from the US Environmental Protection Agency titled, “Maintaining Proper Tire Inflation Pressure, A Glance at Clean Freight Strategies,” driving under the recommended pressure by as little as 10 psi can lead to a reduction in fuel economy between 0.5 and 1%.

Underinflation can cause sidewalls to flex, creating excessive heat and rubber fatigue. Tire wear accelerates in this weakened state, affecting traction, and tires become more susceptible to damage. Additionally, as rolling resistance increases, more power is required to move the vehicle, which increases fuel consumption.

Although the risks associated with improper tire pressure are well known, the time and labor required for proper examination can be a hindrance. Traditional walk-around tire inspections that involve taking a pressure reading of every tire can be an expensive and lengthy process. For a fleet maintenance manager, checking the pressure of each tire on every truck in a fleet can be an extremely daunting task.

TPM: UNRESOLVED CHALLENGES

Systems that monitor tire pressure have been on the market for decades. A tire pressure monitoring system (TPMS) checks the pressure and temperature of each tire and sends an alert to the operator when it drops below a preset value. The ability to detect a potential tire problem and prevent failure provides a major safety and efficiency advantage. But, a TPMS doesn’t address the need to adjust the tire pressure and every system does not indicate which tire has the issue, which means an operator or fleet manager still has to check every single tire.

Systems that self-inflate tires take proactive maintenance one step further and use compressed air to inflate a tire when it falls below the correct pressure. These aftermarket systems typically route air through hoses outboard, which connect to the tire valve and supply air to the chassis and cab. But, with long runs of these hoses exposed to the elements, the possibility for damage is increased and they may even be susceptible to theft.

MEETING OPTIMIZATION NEEDS

Dana has been a longstanding leader in tire pressure optimization with decades of experience building tire pressure management technology for the US military. Drawing on this expertise, Dana’s engineers have developed an innovative product for the commercial vehicle market that is capable of satisfying the significant unmet needs that exist today.

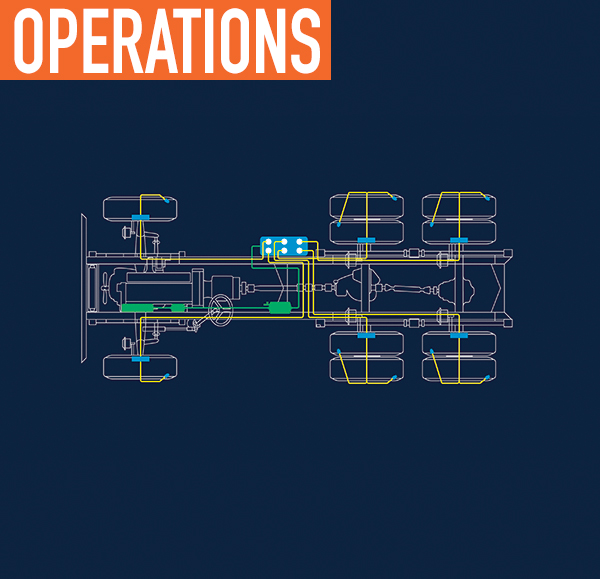

The Spicer® Optimized Tire-Pressure Management System automates tire pressure checks and adjustments to increase uptime, extend tire life, and eliminate failures. The industry’s first fully integrated and electronically controlled system—that also includes integrated steer axle support—Dana’s technology automatically takes action on data that a monitor-only system would merely report, with the capability to detect tire pressures and inflate or deflate to optimum levels when required. This allows fleet managers to eliminate dependence on the malfunction indicator lamp to alert the driver to potential problems, freeing the driver from making judgment calls that could affect safety and efficiency. Additionally, downtime is reduced for operators since the need to pull over to check each tire is eliminated.

THE INs AND OUTs

Engineered for a range of commercial vehicle and vocational truck applications, including linehaul, regional haul, oil and gas, logging, construction, and fire and rescue, this system will be installed at the OEM level and an electronic control unit will communicate issues requiring immediate attention to the dashboard display. Dana’s system will be capable of communicating with any other electronic module on the vehicle via the J1939 CAN bus and standard messaging protocols.

Additionally, the system can be integrated into a telematics package via J1939 connectivity, a major advantage over currently available decentralized automatic inflation systems. This connectivity allows data to be sent back to home base, where it can be collected and analyzed over time to detect trends and a prognosis on each tire’s health can be made.

FOR MORE INFORMATION:

Dana Holding Corporation, one of the world’s most influential automotive suppliers, continues to expand its product array, technological expertise, and geographic scope. Dana fosters a progressive, people-oriented culture that adds a different dimension to the products and services the company provides. Find out more about Dana’s products and services, visit www.dana.com.

_______________________________________________________________________

MODERN WORKTRUCK SOLUTIONS: MARCH 2016 ISSUE

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern WorkTruck Solutions magazine.

![]()