Driving a commercial vehicle doesn’t have to mean fatigue, discomfort, or general unpleasantness. It also doesn’t have to mean low efficiency and high CO2 output. More truck manufacturers are adding passenger vehicle-like touches to cabs while transmission manufacturers are adding fatigue reducing features to new products. And, there is no shortage of applications aimed at improving a fleet’s carbon footprint. Now, Bosch is adding driver experience enriching products to its line in order to bring passenger car comforts and efficiency to fleets everywhere.

Bosch’s ESI Truck delivers true diagnostics and fleet maintenance information for fleet managers powered by connectivity.

SHOWING OFF THE GOODS

“We have a rich history on the passenger car side and, from a commercial vehicle perspective, we’ve also been bringing some solutions to market for a number of years. We’re really seeing that the same mega-trends driving our passenger car side of automated, connected, and electrified are also driving our commercial vehicle side,” says Tim Wieland, media and public relations manager, Bosch.

During this year’s Mid-America Trucking Show (MATS), the Bosch team addressed the three aforementioned mega-trends. “At MATS, we were looking at improving safety and comfort for drivers from an automated perspective. From an electrified standpoint, we looked at everything pertaining to energizing the powertrain. From a connected standpoint, empowering connectivity—that’s a key area, as well—we had a connected trailer solution that we were showing,” says Wieland.

The Bosch team also showed off aftermarket service solutions, like its ESI Truck that, through connectivity, is powering true diagnostics and fleet maintenance information for fleet managers. “The star of our show was Servotwin, which really showcased our future view for enhancing driver safety and comfort. It allows some immediate benefits, but also some longer-term possibilities from an automated perspective,” says Wieland.

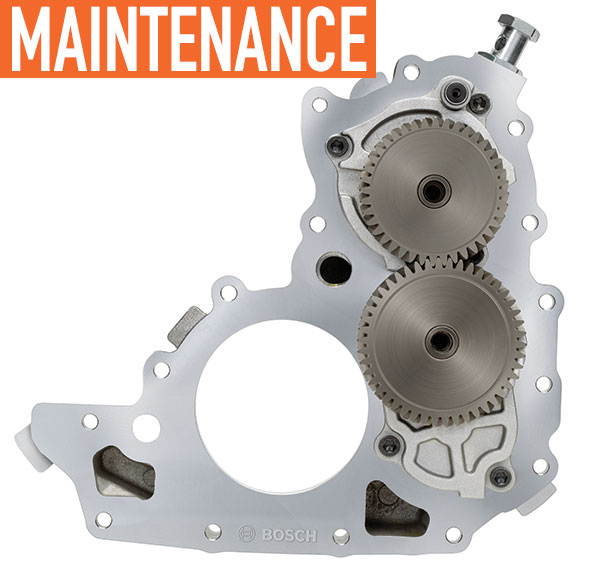

Featured Image: Bosch’s variable displacement oil pump, plus integrated vacuum pump eliminates the need for additional electric or engine driven pumps.

Above: Bosch’s Servotwin offers immediate benefits, as well as possible long-term benefits for enhancing driver safety.

THE MANY-FEATURE PRODUCT

“The Servotwin is basically a hydraulic gear to which we can add all the nice features that evolved out of the passenger car world—comfort and safety—all the driver assist functions, starting with lane keeping, crosswind compensation, and lower efforts for parking,” explains Ulrich Bidlingmaier, application engineering manager, commercial vehicle, Bosch. “Eventually, Servotwin will bring all those features that make it nicer and easier for the driver. On top of that, you can potentially add safety features down the road—accident avoidance and being able to integrate that with the OEM.”

The Servotwin offers more than just one or two features; it’s a stepping stone to a host of benefits. “It’s basically an enabler—a building block—to add all those features to the truck world that the passenger car world has been enjoying for quite some time. Looking at future technologies, it’s also an enabler for platooning, if you have two or three trucks following each other,” says Bidlingmaier. “Basically, it’s an extrication of the overall heavy truck world getting a lot of those features from the passenger car world and, in addition to that, some sort of redundancy in safety. For example, should the main hydraulic system fail, you have some sort of electronic backup that would be able to bring the truck to a safe stop.”

So, when can we expect to see the Servotwin and begin to experience all it can potentially offer? “The Servotwin, the very basic functionality for just initial driver comfort, has been out in Europe since 2013. We’re rolling it out in the US in the upcoming years and lane keeping is going to be one of the first functions—and one of the easiest—to implement into the truck market. While truck OEMs will need to make changes on their side, it’s just software updates and enabling and integrating other functions as desired—they’re customer specific or OEM specific.”

SYSTEM IMPROVEMENTS

Bosch is also offering something that applies to that little thing on everyone’s mind known as efficiency. Of course, this form of efficiency and CO2 reduction comes in a package of which you may not immediately think. “Obviously, these days, everybody is looking to get everything they can in terms of efficiency and CO2 reduction out of the powertrain,” says Paul Mercurio, diesel systems marketing manager, Bosch. Enter, the oil pump.

“The oil pump is typically running inside the engine—somewhat forgotten about—but it’s usually running at the same levels as the engine, consuming power or energy at the same rate. Yet, it actually doesn’t have to be. The oil pump is a component that can be regulated to put out more pressure at times and less pressure at others, depending on demand or the load on the engine,” explains Mercurio. “Knowing that, we have a design for an oil pump that has a variable displacement. There’s an electric valve in the pump, which is controlled by the powertrain controller. It can tell in real time the load on the engine and the demands, so it can determine whether we need a high flow or a low flow.”

“At times when we don’t need a high flow,” Mercurio continues, “it can reduce that load on the engine, making the engine more efficient and also producing less CO2. We also showed a pump at MATS that had the variable

ABOUT THE AUTHOR:

Find out more about Bosch’s products and services, visit www.bosch.us.

_______________________________________________________________________

MODERN WORKTRUCK SOLUTIONS: MAY 2016 ISSUE

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern WorkTruck Solutions magazine.

![]()