It’s likely your fleet managers use a telematics system on their fleets. Telematics systems are revolutionary in their capabilities. They seem to become more and more advanced with every year that passes. We touch on these systems frequently inside the pages of Modern WorkTruck Solutions simply because they are extremely helpful, ever-evolving systems that fleet owners, managers, and drivers come to rely on for smooth operations.

Telematics systems for the chassis are incredibly helpful—just ask any fleet manager how their operations have changed since implementing one. Although these systems make fleet operations more efficient in terms of cost savings and maintenance, common telematics systems lack data for equipment installed on the chassis.

At the Work Truck Show this past March, Stellar Industries unveiled its telematics system specifically for equipment, Stellar Telematics. According to Adam Oppermann, product manager at Stellar Industries, the system garnered interest from both large and small fleets. So how did this system come about, and what exactly does it entail?

“We talked to our customers to see what information they were looking for and what they needed,” Oppermann says. “We heard from the fleet managers that they wanted a full picture of their fleets and their equipment … so that they could make more informed decisions.”

Oppermann believes that overall, fleet managers are looking for the same thing: more data. They want to ensure assets are being optimized in order to make business decisions, such as whether to buy new assets, sell assets, or if an asset could be used more effectively on another project.

MADE FOR MANAGERS

Oppermann says fleet managers want to view their fleet’s data in different ways. “Some people want to view reports from our system and put that data into something they do internally,” Oppermann says. “Other people wanted to have a visual dashboard that … they could just go into and (view) the majority of their needs.”

From that feedback, Stellar Industries created a dashboard for fleets of all sizes so that managers can view the data that is most important for their operations. The dashboard allows managers to easily move their asset data from the dashboard to an internal system for additional analysis or to combine with other fleet data. Stellar designed the system to be as flexible as possible so that any fleet can see the information that is most important for them.

Oppermann says the system received positive feedback from the Work Truck Show as well as CONEXPO where the telematics system was also on display. Although the feedback was positive, there were also some interested fleet managers who made a few suggestions. Just as Stellar listened to customer input while developing the system, they used the feedback from the trade shows to make even more enhancements. For example, Stellar Telematics provided compressor usage information by breaking down data into hours and daily minutes prior to the trade shows. But Oppermann says fleet manager feedback showed a desire to see information on how much a compressor was running for loaded hours and producing air—idle time versus working time. Now, Stellar Telematics provides that metric and updated the dashboard for managers to see that data at a glance.

PILOT PROGRAM

Before Stellar Industries introduced its system to the market, the company put it through pilot testing. “We started off with a pretty large fleet as one of our partners throughout testing,” Oppermann begins. “Just going on a customer journey with them to figure out what they’re looking for.”

As the system progressed, Stellar rolled it out to another fleet for pilot testing, gathered the fleet’s feedback, made enhancements, and rolled it out to yet another fleet. “We kept expanding our pilot program until we had a pretty diverse group of people looking at it to make sure we were doing the best we could to hit the vast majority of needs out there,” Oppermann explains.

SYSTEM BENEFITS

Feedback from the pilot program also highlighted the importance of a system that improved preventive maintenance. Stellar Telematics gives fleet managers the option to send preventive maintenance alerts to any employee in a company. These maintenance reminders help fleets keep tabs on their equipment. Without these reminders, preventive maintenance could go unperformed and potentially cause downtime or complete equipment replacement, cutting into a fleet’s bottom line.

Additionally, the system’s robust data collection allows fleet managers to use the data to determine lifecycle of each piece of equipment connected to Stellar Telematics. Oppermann says some fleet managers capture equipment data specifically to determine how their equipment is used. This includes aspects such as operator behavior to ensure equipment is used properly as well to ensure the equipment used is adequate for the job.

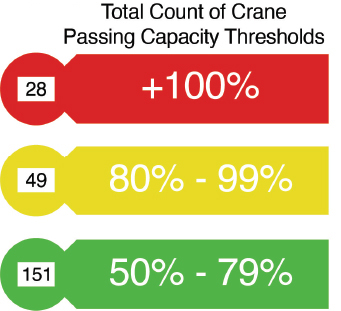

An example Oppermann shares is that if an operator notifies a fleet manager that a larger crane is needed for a job, the manager would be able to review the data of the crane to determine if it is used near to capacity a majority of the time. This data (example shown below) gives the fleet manager hard evidence whether equipment should be reallocated or acquired to meet the needs of the job.

Additional benefits of Stellar’s system are operator controls and diagnostic tools. The WiFi Module allows an operator to control lights, the PTO, and turn the air compressor on and off through an app on their cell phone. The app also shows the status of electrical components. This status is also accessible to Stellar’s customer service team. If an operator encounters an issue, customer service can remote into the truck and determine the issue within a few minutes.

USING THE SYSTEM

Stellar Industries’ telematics system features a long list of trackable data points—even down to the running hours of individual flood lights—that are displayed on the dashboard or available to fleet managers through reports. This wealth of data is extensive, therefore to decrease information overload, fleet managers can view more actionable data on the dashboard. Data from other aspects such as the use of flood lights can be found in reports.

Oppermann says perhaps the best way to use Stellar Industries’ system is to look at your fleet’s trends. Look for your fleet’s average usage points and lifecycle. Are there any outliers among your fleet? Are some pieces of equipment working harder than others to perform the same task? If there are major outliers in your fleet, look into the situation. It’s possible that there is a problem with the equipment you’re running or that the equipment is operated incorrectly.

Of the fleets that have already adopted Stellar’s system, Oppermann says some have already expanded the system to other locations within their fleet. And why wouldn’t they? With Stellar’s preventive maintenance notifications, fleet managers don’t have to keep track of the maintenance themselves and are able to focus more on the job at hand—not to mention the potential savings due to less downtime and fewer equipment replacements. Stellar’s system also allows its customer service team to diagnose equipment issues much faster and get a better understanding of how each asset is used on the job.

Stellar Industries’ goal was to satisfy fleet managers’ need for a broader view of equipment usage, and with Stellar’s equipment telematics system, that’s just what fleet managers get.

FOR MORE INFORMATION

Stellar Industries manufactures hydraulic truck-mounted equipment including hooklift hoists, cable hoists, container carriers, telescopic cranes, articulating cranes, and work truck accessories. Find out more about the Stellar Telematics system, visit www.stellarindustries.com.