Trucks spend a lot of time of time on the road. It’s important to not let the road spend a lot of time on your trucks.

Outside of the comfort of their terminal or garage, there are road salts, deicers and other chemicals, and road debris that make for a harsh, corrosive environment just waiting to attack your trucks and their wheels mile after mile. There can also be acid in truck washes, which can further add to the damage.

Winter months are especially bad for your equipment. Navigating tough terrains and challenging conditions means fleets need reliable wheels that provide protection from any environment to keep them lasting longer and looking their best.

For steel wheels, those challenging conditions can easily lead to rust, even when the wheels are coated. For aluminum wheels in these conditions, they typically must be polished to keep them shiny. Over time, an oxide starts building up and it gets thicker, and the wheel becomes duller and duller. Polishing, which requires a decent amount of effort, removes the outside oxide layer to bring back the bright shine of the raw aluminum.

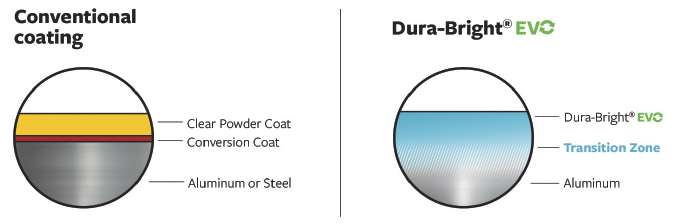

Conventional coatings can be used to protect the aluminum underneath, but they essentially lie on top of the surface without bonding to it. Using an acrylic clear coating as an example of one of these conventional coatings, it sits on top of the aluminum. Eventually, corrosion can get underneath the coating and can continue to spread. This is called filiform corrosion, and it looks almost like snowflakes forming. If the surface of an acrylic clear coat is scratched, corrosion will grow underneath the coating.

BETTER PROTECTION

An alternative to conventional coatings is a surface treatment that interfaces with the base aluminum to form a molecular bond. In essence, it becomes part of the wheel itself. Scientists at Alcoa Wheels had the goal of creating a new type of treatment that would interface with the base aluminum. Their research, development work and testing led to the creation of Alcoa Dura-Bright surface treatment and the advent of Alcoa Dura-Bright wheels.

The surface treatment on the wheels is engineered to endure the harshest conditions, combating corrosion, and maintaining a shiny, brand-new look with minimal maintenance. Since the surface treatment forms a molecular bond with the wheel, it won’t crack, peel, or corrode like coated wheels, keeping it looking newer for longer without polishing or painting or time-consuming cleaning. The technology has been tested and proven in harsh conditions throughout the years.

SCIENCE ON THE SURFACE

From a scientific perspective, the surface treatment is distinctive because it provides a wheel with extremely low surface tension where there are intermolecular forces that repel water, dirt, and chemicals. It creates a barrier around the wheel to ensure they remain shiny and corrosion free regardless of the road conditions. The lower the surface tension, the less likely dirt will stick.

A water droplet is a good indication of surface tension, which is measured by the angle water droplets bead up. An untreated polished aluminum wheel has a medium contact angle and water droplets flatten out slightly with some puddling, indicating a medium surface tension. A painted steel wheel has a lower contact angle, indicating a higher surface tension. It allows water to flatten out and puddle, and dirt to stick.

In testing, water droplets on the painted steel wheel slowly roll off while water droplets on the treated wheel rolls quickly off and leaves nothing behind. That’s because they have a larger contact angle, indicating a lower surface tension, which keeps water beading and dirt from sticking.

EASIER CLEANING

As a result of the production process penetrating the aluminum, the surface treatment ensures that wheels not only shine bright but stay that way even after hundreds of washes and thousands of miles without polishing.

Wheels with the surface treatment can be easily cleaned with mild soap and water, eliminating the need for harsh cleaning products, further protecting the environment, and reducing maintenance costs and downtime. The first cleaning step is a water pre-rinse followed by applying the soap or detergent using a spray applicator, a soft bristled brush or soft sponge, and then finally a clean water rinse.

For More Information

To learn more about how Alcoa Dura-Bright Wheels are engineered to outlast and outshine, and how they can save time and money by keeping trucks on the road more and looking their best with a lot less effort, visit: www.alcoawheels.com/north-america/en/durabright/.