Anyone who’s ever secured cargo with chains knows that simply getting the chains in position to begin securing the payload can be quite a task. Thirty-ft lengths of half-inch, 100-grade steel chain can weigh as much as 85 lbs each, 98 lbs if you carry the necessary 15-lb load binder at the same time. Now, multiply that by the number of chains that may be needed to adequately secure a load, and you can be talking about a lot of cumulative weight.

“We use a different amount of chain for each load depending on the load weight and available securement points,” says Ace Carter, engineer for Northwest Logistics Heavy Haul, an Oklahoma-based heavy-haul service provider doing business throughout the US and Canada. “A theoretical load requiring 14 30-ft, half-inch 100-grade steel chains and binders with a 15,000-lb working load limit (WLL), would add up to about 1,372 lbs of securement. Simply deploying this is a long and strenuous task for even a two-man crew.”

SHACKLED

Once the chains are situated around a trailer and its cargo, the real work begins. Some cargo items have engineered anchor points that enable workers to connect load securement devices directly to the cargo. This is known as “direct” securement. Other cargo articles have nothing to attach to, so the securement has to pass through, over, or around the article. This is known as “indirect” securement.

Carter says that on larger loads like tanks, a team of two would generally be used to secure the load. One person usually throws a guide rope, attached to the chain, over the tank to a second person on the opposite side of the trailer, who then pulls the chain up and over the vessel as the first helps guide it. “Either way,” Carter begins, “steel chains take time to set and secure, and it’s physically demanding work.”

Steel chains aren’t just heavy, they can also be abrasive. When using them, Northwest often had to use carpet, rubber, fire hose, and other liners to protect their cargo’s finish from damage. The process sometimes required climbing ladders and the use of manlifts or forklift baskets. This led to more materials to buy, transport, store, and maintain. More care was also required when handling, orienting, and securing heavy chains to avoid damage to payloads that could ultimately result in customer dissatisfaction.

THE MISSING LINKS

In 2018, Carter and Northwest began exploring a cargo securement technology from Doleco USA that promised to alleviate some issues surrounding the use of steel chains for cargo securement. Doleco’s new product had the potential to completely change Northwest’s approach to load securement with steel chains.

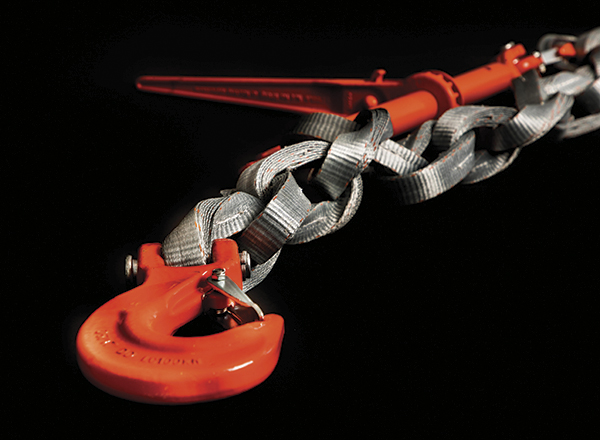

Doleco’s DoNova® PowerLash Textile Lashing Chain and Tie Down System is made of high-performance Dyneema® fiber. Dyneema’s ultra-high-molecular-weight polyethylene (UHMWPE) material is 15 times stronger than steel by weight, and when made into chain, up to 85% lighter—so lightweight, in fact, that it floats on water.

“The DoNova PowerLash Textile Lashing Chain has extremely low moisture absorption, is self-lubricating, is highly resistant to corrosive chemicals, and is 15% more resistant to abrasion than carbon steel,” says Ralph Abato, president and managing director of Doleco USA. “The textile chain is available with a WLL as high as 22,000 lbs, more than that of half-inch steel chain and just under the 22,600-lb WLL of 5/8-inch steel chain.”

Northwest’s crews needed only 10 DoNova PowerLash Tiedowns to do the job of 14 steel chains. Coupled with other tangible benefits, Northwest decided to give the DoNova product a try.

“Less weight means easier handling, less fatigue, and a lower potential for injury,” Carter says.

Carter notes that now his folks can toss the guide rope over and pull the lightweight DoNova PowerLash Textile Lashing Chain over a tank and secure both sides without worrying about scratching the tank’s finish. He believes that DoNova chains save time and effort while reducing worker fatigue and risk of injury.

“Now we have less effort required for securement, less risk of personal injury, less gross weight to haul and permit, fewer securement devices required on some loads, and the 10-metric-ton-capacity matches securement points on many of our European trailers,” Carter says.

CHAIN-GING THE GAME

Securing cargo on an open-deck trailer can be daunting at times. Construction materials and equipment in particular present challenges. Those securing cargo and vehicle operators must be familiar with federal regulations and must have a working knowledge of the physics of how cargo behaves once it’s in motion.

Depending on the type of load and the requisite securement method called for, those doing the securing have a number of decisions to make. Some cargo types are simpler than others. Some are downright complicated, requiring significant physical effort. Some loads may be heavy, have sharp edges, or be prone to shifting. Climbing into, onto, and around items in order to attach restraints can expose workers to a host of hazards.

“Maybe your heavy-haul drop deck or lowboy trailer is carrying large or articulating equipment to and from an off-highway worksite,” Abato says. “If so, you have to know that any and all hydraulic arms need to be secured, and that any dirt and rocks left on the deck may be considered ‘unsecured cargo’ by the authorities.”

The extremely low weight and flexibility of DoNova PowerLash chain promotes easier handling of heavy-duty load securing devices. It can be easily thrown over large loads or guided around complex cargo geometries without damaging them or their finish. With DoNova, individual workers can handle long lashing chains of more than 60 ft all by themselves.

The textile chains can also be shortened very quickly since all hooks of the tensioning device can be attached directly to the flexible chain links. This chain is particularly well suited for heavy use since it is extremely resistant to abrasion, chemicals, and even seawater.

TANGIBLE CONTRAST

Doleco also developed load binders for the DoNova Textile Chain. At just three quarters as long as a standard load binder, the DoRa® Ratcheting Load Binder fits into spaces but expands to enable users to reach twice as far as any other. The compact size and extra length of the DoRa save users time and trouble because they don’t have to detach and reattach chains when periodically retensioning cargo.

“Doleco’s DoRa Ratcheting Load Binder is 20% shorter than others, extends to twice their length, and makes chain retensioning a breeze,” Abato says. “The patented spindle-in-a-spindle design of the DoRa Ratcheting Load Binder … is designed specifically to work as a system with Doleco’s DoNova PowerLash Textile Lashing Chain.”

With its WLL of 22,000 lbs, the DoNova PowerLash 25/8 may be used with the lashing strap as a tensioning element. Doleco’s Heavy Duty 2-inch Ratchet with Gear Drive features webbing made with Dyneema and special eye hooks and coupling links that can substitute for standard load binders. It also gives the system an increased tensioning range at a reduced weight. The WLL of the tensioning elements employed (straight pull or loop) are easily matched to the WLL of the textile chain and hooks effortlessly into their respective chain elements.

DoNova can also be used as a head sling. If a load has no fastening points, it can be secured with a sling that runs over and/or around the cargo.

Few new products offer the quantity of dramatic advantages delivered by Doleco’s advanced textile chain technology. The contrast between steel chain and the DoNova PowerLash Textile Chain is quite tangible.

“All I have to do is let folks hold a steel chain in their bare hand and a DoNova Textile Chain in the other,” Abato says. “People immediately understand that this is an advancement in material engineering and industrial design that will have implications that extend far beyond cargo securement—there’s almost always a slight look of awe on their face.”

FOR MORE INFORMATION

Find out more about Doleco USA and its DoNova PowerLash Textile Chains, visit www.doleco-usa.com.