Heavy haulers know the story all too well—when hauling the heaviest loads on the road, finding the right coupling equipment can be challenging.

A big issue is weight capacity. Many manufacturers that produce pintle hitches do not list the capacities, and for anyone in the heavy haul industry, that is a non-starter. Given the inherent dangers of trailer separations, one must know the weight capacity for any pintle hitch. The US saw nearly 1,000 accidents involving trailer separations from 2009 to 2018, and whenever trailer separations occur, they almost always involve a fatality. From 2009 to 2018, 1,156 people were killed in trailer separation accidents.

SAFETY NETS

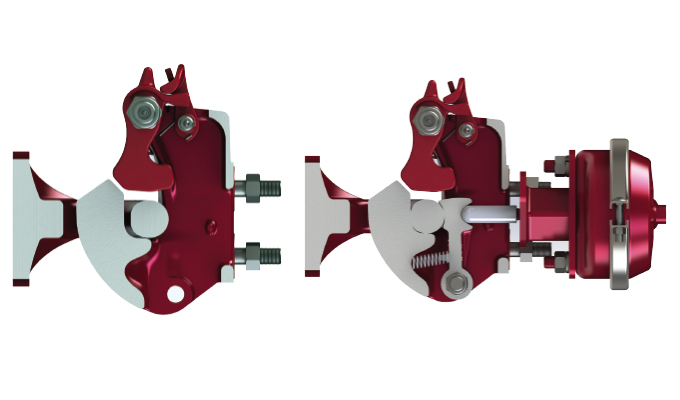

Because of this grave concern, some coupling manufacturing companies have invested a lot of time and resources into developing new technologies. In fact, there is one new hitch on the market that closes with the release of the emergency brakes. While making sure the latch is closed correctly is always the responsibility of the person making the coupling connection—and it’s the driver’s responsibility to verify that the equipment is correctly connected prior to moving the vehicle—mistakes happen, and a great Plan B is invaluable. Any coupling that can help prevent catastrophic accidents saves countless lives in the process. Fleets are taking note and starting to pick up on these life-saving trends.

Another feature that affords greater comfort and safety is adding a Type 30 air service chamber for use with a slack-reducing coupling to any heavy haul application. This type of air chamber applies up to 3,000 PSI to dampen heavy loads via the pushrod. Therefore, a Type 30 air chamber is the safest and most reliable for anyone using this style of coupling. By reducing the slack in the connection, the load is hauled much smoother and safer while the coupling equipment benefits from a much longer useful life.

Grade 8 fasteners are a must with all pintle hitch applications, but any heavy hauler should look at grade L9 fasteners to ensure the coupling does its job. With a tensile strength of 180,000 lbs per square inch, L9 fasteners are perfect for high-stress environments and supply the additional strength needed to carry any load down the road with confidence. Fleets should always check with the coupling manufacturer to ensure they are using the highest quality fasteners.

DRAWBAR ASSEMBLY

Of course, when discussing coupling equipment, the pintle hitch only tells half the story. It is also imperative to ensure the drawbar eye’s weight capacity is acceptable for the load and application. A chain is only as strong as the weakest link, therefore the drawbar eye needs to be equally rated for the capacities specified by the fleet.

Speaking of applications, some heavy haulers see rough terrain as part of their run, in which case it is essential to use an appropriate front-end assembly that can handle uneven paths. Some suppliers produce a front-end assembly that contains a swivel drawbar eye, and that tandem can handle the roughest of roads with ease. However, in that case, companies must make sure that the swivel drawbar eye carries an appropriate weight capacity.

If a company experiences rough terrain and is not using a swivel drawbar eye and front-end assembly, the coupling can wear more quickly. Therefore, consider the coupling material before making a final decision. Not all pintle hitch and drawbar eye materials are created equally, so examine the compounds used during the manufacturing process. Some materials on the market actually work-harden, meaning that as friction builds up on the surface of the coupling, the material gets harder and harder. In this way, it is similar to material found in railroad rails.

A set of heavy-duty hinge assemblies will also dampen the load of your drawbar assembly. Pair these with a set of poly bushings, and they will absorb the extreme weight of heavy hauling. Some manufacturers offer hinge assemblies rated at 150,000 lbs. Nylatron bushings are also a great option for many heavy haulers. Nylatron is a NASA-approved material whose characteristics will outperform most polymer materials in a heavy haul application.

GAUGES & GUIDES

Considering the weight involved with heavy hauling, it is essential to monitor the wear of all coupling equipment, and some manufacturers offer accessories to monitor and assess the wear of their products. Using tools such as wear gauges will not only help identify critical wear on the horn and drawbar eye, but they can also help a company plan for any potential replacement equipment. Nobody wants to be caught behind the eight ball without a replacement option on hand, and many wear gauges will indicate when a new product should be ordered. Some wear gauges come with a latch gap measuring device, which, if it passes through the gap between the horn and latch when the latch is closed, recognizes when a coupling should be taken out of service. Wear gauges and latch gap measuring devices can play an important role in properly maintaining coupling equipment.

Some suppliers also provide step-by-step guides to choose the appropriate coupling equipment. This is a huge help for any company in the heavy haul industry. Sometimes, manufacturers even provide an online website tool that walks users through the process of identifying the correct part number.

Ultimately, weight plays the biggest role when selecting the right coupling equipment for heavy hauling, but there are numerous ways to increase safety and make things easier for drivers. When questions arise, its best to reach out to the coupling manufacturer directly for advice on the best coupling equipment to use for specific hauling requirements.

FOR MORE INFORMATION

Find out more about couplings and their equipment, visit www.highbarbrands.com.