By Del Williams

In the transportation industry, regulations require tank trucks that haul food-grade oils to be thoroughly washed out between loads before any new product is introduced. Facilities that clean these tank trucks produce oily water from a combination of the wash water infused with the oil residue clinging to the inside of the tank.

This oily wash water must be disposed of properly. So to comply with the various local, state, and federal EPA requirements in this regard, facilities that clean tank trucks must find cost-effective water treatment solutions involving oil and water separation equipment to remove the residual oil in wash water before it is discharged into the sewer and sent to a municipal facility. Failing such regulatory compliance can be costly. If the water contains too much residual oil after treatment, municipal water treatment centers can refuse to accept it and levy hefty surcharges and fines.

There are other economic benefits to recovering and handling waste oil properly. Once separated from the wash water, the residual vegetable waste oils can be sold at a profit to companies making biofuels.

The process of separating residual vegetable oils from tank truck wash water poses a number of challenges, and the oil water separation process must accommodate a long list of variables. Every tank truck wash facility is different in many respects. The number of trucks that need to be washed, the cycle time of the wash, the type of washing equipment used, truck sizes, types of oils hauled, oil/water ratios, peak periods of use, changing flow rates, environmental conditions, and facility size and layout can all vary greatly from site to site. In addition, these facilities operate in different locations with differing local and state regulatory requirements.

RESIDUAL OIL REMOVAL

To make matters more challenging, certain types of vegetable oils will solidify at room temperature. These include oils that are naturally more highly saturated, such as coconut oil, and other types of vegetable oils that are “hydrogenated” by man-made processes (e.g., palm, soy, canola oil). These types of hydrogenated oils can be particularly difficult to remove from wash water because they require relatively high temperatures during the wash cycle to become and remain liquid. In the tank wash process, the proportion of wash water to oil can also vary during the washing cycles, thus putting a sometimes high and variable demand on the oil water separation equipment that follows.

“Typically, a number of factors influence the ultimate design of an efficient oil removal system, including flow rate, concentration of oil in the mix, specific gravity of the oil to be removed, and temperature, among others,” according to Jim Petrucci, vice president at Oil Skimmers, Inc., a Cleveland, Ohio-based manufacturer specializing in separating and recovering all types of waste oils, greases, and fats from water.

To accommodate all these variables and efficiently remove oil from the wash water, the application should be analyzed by professionals so that the oil separation and removal equipment can be properly matched to the requirements of the application. Ideally, oil removal systems should cost-effectively, continuously, and actively remove food-grade oil no matter the levels of oil concentration, flow rate, or temperature of the wash water with minimal maintenance and direct supervision. Fortunately, such systems exist today and are growing in popularity.

OIL SKIMMERS

At some tank truck wash facilities there are pits or sumps where oily wash water collects and oil separates naturally and floats to the surface. In this scenario, an oil skimmer should be used to remove the floating oil from the surface of the water.

There are a variety of oil skimmers that can be applied to this task. Some use passive oil removal methods such as slotted pipes or overflow weirs. The problem with these methods is they can be labor intensive and require regular monitoring, maintenance, and manual adjustment to perform sufficiently. If they are not maintained and adjusted to meet the flow, they can either take too much fluid—resulting in too much water along with the waste oil—or they can take too little oil relative to the flow—becoming easily overwhelmed with oil and grease—permitting an oil layer to form on the surface of the water. Oil buildup can lead to bacteria growth, creating odors and health risks and bogging down the effectiveness of the separation process. These passive skimming devices are primary causes of excessive maintenance requirements and poor performance issues in oil water separation situations.

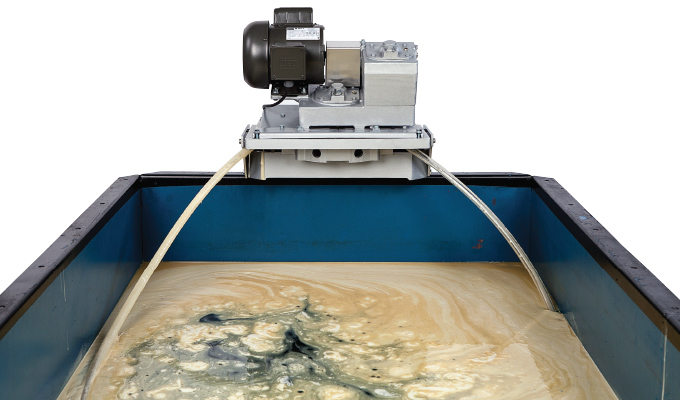

An efficient and effective way to remove the oil after oil and water separation is with an oil skimmer that uses a Free-Floating Collector Tube™. Tube-type oil skimmers actively and continuously remove oil 24/7 as it rises to the surface of the water. As the tube moves across the surface, oil adheres to the outside, then the tube travels through a series of ceramic scrapers that remove the oil. The recovered oil drains into a collection vessel. Tube skimmers are not affected by water level fluctuation or floating debris and solids, remove very little water in the process, and operate continuously with minimal attention or maintenance.

IN THE FIELD

One successful example of oil skimmer in use involves a Midwest-based trucking company with a fleet of over 200 tanker trucks—many used to haul soybean oil. The trucking company cleans its trucks after each job. Each tanker hauls approximately 48,000 lbs of oil, so a material amount of residual oil clings to the inside of the tank and mixes with water during the wash cycle.

Local regulations require the company to remove all residual oil from the wash water before discharging it into the sewer system. When the trucking company assessed its existing oil removal process, it found glaring inefficiencies.

To clean out the tankers, the maintenance crew sprayed water into the trailers and emptied the oil-infused wash water into holding tanks where the crew had to manually skim the oil from the surface of the wastewater. This practice met local wastewater regulations but was inefficient and labor intensive. As a result, the company’s operations manager sought a more efficient and cost-effective method to remove oil from the wastewater before it was treated further in the company’s existing dissolved air flotation (DAF) unit.

The company decided to install a Model 5H Brill® tube-type oil skimmer, mounting it directly on the edge of its main wastewater holding tank. Subsequent to the installation of the tube-type oil skimmer from Oil Skimmers, Inc., the trucking company no longer needed to manually collect sludge from the wastewater, delivering substantial labor savings. The company notes that the oil skimmer is so effective it enhances the performance of its DAF unit and reduces the amount of flocking agent required, further reducing costs.

According to the company’s operations manager, the oil skimmer saved enough time and money to more than pay for its cost within a few weeks, while helping the company easily meet wastewater requirements.

NEXT TIME

Be sure to check out next month’s issue for part two, discussing oil water separators for more difficult applications when the waste oil does not have the time or the space to rise naturally to the surface of the water.

ABOUT THE AUTHOR

Del Williams is a technical writer who lives in Torrance, California. Find out more about oil skimmers, oil removal systems, and how to design an oil water separator for your application, visit www.oilskim.com.