This issue features a double focus: Trucks in Landscaping and Future Forward—after all, it is a new year! Vehicles traveling from jobsite to jobsite in cold months, landscape or otherwise, makes us wonder how electric vehicles (EVs) would perform in the same arena. We chatted with Gina Bonini of Modine to gather insight on the differences between using EVs versus conventional vehicles in cold weather.

MWS: CAN YOU GIVE A RUNDOWN OF MODINE’S HISTORY IN THE AUTOMOTIVE SECTOR AND HOW IT’S EVOLVED TO BECOME A PROMINENT PLAYER IN THE MODERN AUTOMOTIVE INDUSTRY TODAY?

BONINI: Modine’s history in transportation goes back to when we were founded in 1916 by a young engineer and innovator, Arthur B. Modine. In 1925, Modine began manufacturing the radiator for the Model T Ford, entering mass manufacturing for the automotive industry and scaling up the company. This foundation of innovation has continued throughout Modine’s history, and in 2018 we began design on our Battery Thermal Management System (BTMS) for commercial electric vehicles.

Today, Modine, headquartered in Racine, Wisconsin, leverages 100 years of thermal management experience to offer start-to-finish services from design to validation testing and scaled production for commercial electric vehicles. Our EVantage BTMS solution is a complete, plug-and-play thermal management system that can be customized to meet customer needs and specifications.

MWS: SOME FLEETS HAVE ALREADY TAKEN THE PLUNGE WITH ELECTRIC VEHICLE (EV) PURCHASES. ALTHOUGH THESE VEHICLES PERFORM SIMILAR FUNCTIONS AS VEHICLES WITH CONVENTIONAL ENGINES, THEIR OPERATION IS DIFFERENT, WHICH MEANS THEIR MAINTENANCE REQUIREMENTS ARE DIFFERENT. AS WE GET CLOSER TO WINTER, WHAT SHOULD EV OWNERS KNOW ABOUT HOW COLD TEMPERATURES CAN AFFECT THEIR EVS?

BONINI: First, let’s talk about range. For electric vehicles, cold weather can reduce range by up to 40%, according to Recurrent Auto. Nearly two-thirds of the range reduction is due to extra draw on the battery to heat the cabin—heaters, heated seats and steering wheel, and defrosters. The less cabin heating required, the lower the impact on the battery’s range.

The next significant factor is lower battery performance. The optimal temperature for a battery pack is 77 to 95 degrees Fahrenheit. As the temperature drops, the battery is less efficient, causing it to deplete a charge faster and take longer to recharge. To ensure optimal range and charging time, a battery thermal management system with a heating loop will be essential to keep the battery pack between 77 and 95 degrees during both charging and operation.

MWS: DO THESE ISSUES AFFECT ALL EVs, EVEN LARGER ONES SUCH AS THOSE IN CLASS 3-6? ARE THERE ANY DIFFERENCES IN HOW LARGER EVs (WITH LARGER OR MULTIPLE BATTERY PACKS) ARE AFFECTED?

BONINI: You can think of the battery pack of an EV as thermal mass. A larger truck or one that pulls a heavier load will likely require a larger battery pack. If this truck sits outside in frigid weather, the battery pack will continue to cool down until it reaches equilibrium with ambient temperature. The larger the battery mass, the longer it will take to warm the battery pack to optimal temperature when it’s time to start using the vehicle. Plugging in whenever possible, especially during extreme temperatures, will greatly benefit these larger commercial EVs. Keeping the vehicle plugged in allows the BTMS to maintain the temperature on the battery pack and avoid extremes. Of course, parking or storing the vehicles in a heated space is also a good option.

MWS: WHY IS IT SO IMPORTANT TO MANAGE THE TEMPERATURE OF EV MOTORS? WHAT COULD GO WRONG IF TEMPERATURES AREN’T MANAGED WELL?

BONINI: On an EV, managing temperature is important for the inverter, converter, and traction motor for performance, durability, and safety. In general, heavy-duty vehicles demand more power during operation than the average light-duty vehicle or car, requiring consideration of thermal management for the power electronics. For the inverter, the power output will rely on the maximum temperature limits of its power module, which runs the risk of overheating and shutting down if the temperature is not managed.

Commercial EVs typically have a cooling package for the inverter, converter, and traction motor. Each of these power electronics will have a coolant loop to cool them down. This coolant is then routed through the cooling package to reject the heat before circulating back through the power electronics. This circuit keeps the power electronics at the optimal temperature for performance and to minimize damage.

MWS: IS IT ONLY UP TO THE OWNER TO MANAGE THE EV’s TEMPERATURE, OR DO THESE VEHICLES HAVE THEIR OWN TEMPERATURE MANAGEMENT SYSTEMS?

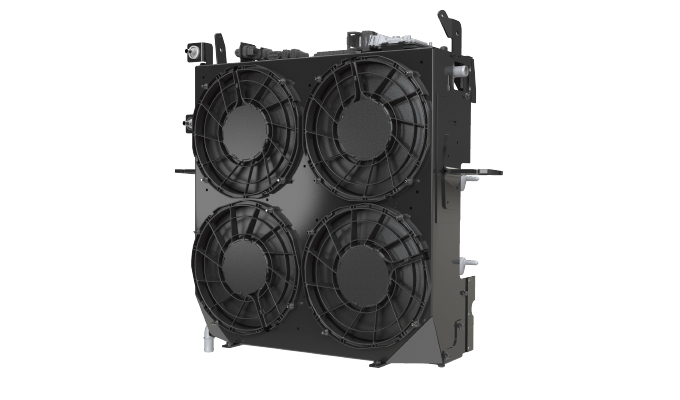

BONINI: A battery thermal management system (BTMS) is common for commercial electric vehicles. A BTMS will provide heating or cooling depending on the battery pack’s temperature. During a cold winter day, the BTMS can heat the coolant that circulates around the battery pack to maintain its optimal temperature. During a hot summer day, the BTMS will cool the coolant to maintain the temperature at the optimal state. A key consideration with a BTMS is optimizing cooling while minimizing power draw. To do this, some BTMS units will include a passive cooling loop, which uses a radiator and fans to reject heat, and an active cooling loop, which uses a refrigerant circuit.

MWS: DOES TEMPERATURE MANAGEMENT FOR EVs ONLY AFFECT ITS PERFORMANCE, OR CAN PROPER AND IMPROPER TEMPERATURE MANAGEMENT AFFECT OTHER ASPECTS OF THE EV?

BONINI: The life cycle of lithium-ion batteries relies heavily on stress factors like storage conditions and operating temperatures. Temperature can also impact the battery’s performance, safety, and capacity. According to Lithium FAQ, lower temperatures can reduce the capacity as the chemical reactions inside the battery slow down. In extreme cold, the battery may even stop functioning. For high temperatures, the chemical reactions in the battery speed up, draining the battery at a higher rate. Permanent degradation can also happen with continued exposure to high temperatures.

Fortunately, a BTMS helps maintain a battery pack at its optimal temperature of 77 to 95 degrees regardless of ambient temperature, improving time to charge, optimizing range, and minimizing degradation of the battery pack.

MWS: ADDITIONAL THOUGHTS?

BONINI: Commercial electric vehicles should have a battery thermal management system in place that is designed to regulate battery temperature in a way that maximizes range and minimizes charging time.

For More Information

Gina Bonini is the vice president and general manager of Advanced Thermal Systems at Modine. Find out more, visit www.modine.com.