Equipment asset awareness has never been more critical, especially in today’s rapidly changing economy. Reviewing contract renewals and equipment replacement cycles is difficult for many construction companies, as one study shared by CloudCover (2023) shows that 91% of companies do not have a dashboard that tracks renewal status. This is so important that the business world dedicates the entire month of March acknowledging the importance of asset awareness.

As such, March serves as a special reminder to construction businesses that, no matter the time of year, it’s essential to understand how improved asset management practices can contribute to their organization’s overall mission and revenue goals. Asset management is vital to any organization looking to properly manage its fleet of trucks and equipment.

No matter the kind of organization, the benefits of asset management are valuable:

- Improve budgeting and planning

- Increase efficiency

- Manage equipment and improve maintenance

- Provide compliance with regulations

SCRUTINZING CONTRACTS

Asset management is especially critical today because flexibility is at the forefront of every successful business strategy when operating a fleet of trucks in construction. Today’s top fleets realize they must scrutinize every detail of each truck’s lease structure since the contract can mean the difference of millions gained or lost toward their bottom line. To help executives maximize their asset management strategies, asset management firms are providing a full suite of data analytics to determine the best finance option for their operation.

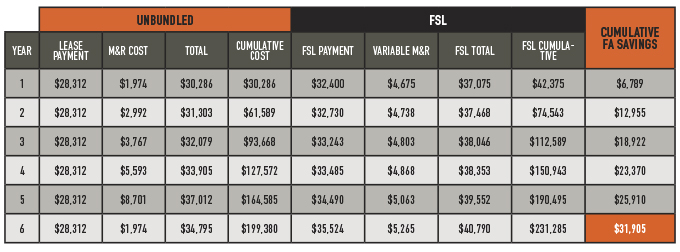

These tools are needed to help fleets and construction businesses make better decisions because finance costs are a significant calculation in any equipment acquisition. The most effective process to reduce truck and finance costs is to have competitive finance options. For example, competitive options can be achieved when full-service lease agreements are unbundled, allowing the freedom and flexibility to shop for the most competitive options. To determine if unbundling is a good fit for an operation, a UBL/FSL Comparative Cost Analysis should be utilized.

In the example provided (Image 1), the calculation captures significant savings in a UBL compared to finance/monthly costs against an FSL ($31,900 per vehicle), even for daycab trucks running roughly 55,000 miles per year. The CPI increases are based on actual history (4.0% Cap). These amounts will differ by cab type, application, utilization, and OEM, but savings versus a traditional FSL will likely be achieved.

In addition to a lease type analysis, various metrics should be deployed, such as the lease versus purchase analysis, lease versus loan analysis, sales tax analysis, etc.

STARTING POINT

Every truck has a different in-service start date and keeping track of all units is cumbersome but imperative. In addition to monitoring Total Cost of Ownership (TCO) expenses, construction-focused organizations must analyze their complete truck life cycle data to determine when trucks are nearing the right time for a replacement, starting at 18 to 20 months before contract expiration.

It is also important not to get locked into a financial structure that does not match the usage of the asset, which could limit the flexibility to get out when the market changes or when it’s time to pivot.

When reviewing contracts and various in-service dates, some important checklist items include:

- Monitoring lease expirations by truck

- Checking if there is flexibility to exit the lease in 90 days

- Determining what type of extension provisions are in place

- Checking if the fleet is locked in a contract with limited options

- Evaluating if the fleet can produce a true Cost Per Mile (CPM)

Regardless of what type of lease or financing is being utilized, fleets with construction equipment must determine what is included and conduct a line-by-line comparison for each cost of item, such as the lease payment, warranty, maintenance and repair cost (whether in-house or outsourced), licensing, tires, etc.

Around six to nine months (considering current build slot availability) ahead of the truck’s optimum replacement window is the right time for fleets to determine whether they should plan for a new acquisition type. This should be a part of an organization’s one-, two-, and three-year procurement strategy and holistic asset management approach, which evaluates factors such as corporate structure, balance sheet, interest rates, residual values, tax benefits, depreciation, etc., in making decisions.

DATA AND RESOURCES

Asset management partners help fleets gain an extra competitive edge because they leverage advanced data analytics to performance analytics, such as a Comparative Cost Analysis, to determine the optimal time to upgrade equipment and even what type of equipment. Furthermore, operating data is used to build customized fleet modernization plans using pioneering tools, such as emissions calculators to procure newer trucks that preserve both the bottom line and the environment.

With all the economic changes, executives operating fleets for construction must utilize every possible resource to manage their asset portfolios properly. Today’s fleets continue to seek advanced data-driven tools that can help offer insight into their decision-making, which is why it’s critical to work with a holistic asset management partner that can help maximize efficiency and reduce cost at every opportunity.

With this approach in mind, these businesses will realize how more robust asset management practices will contribute to their organization’s overall mission and revenue goals.

About the Author

John Rickette, CTP, is vice president of Portfolio and manager of the Transaction Management Team at Fleet Advantage, a leading innovator in truck fleet business analytics, equipment financing and lifecycle cost management. For more, visit www.fleetadvantage.com.