This second article in a two-part MWS series, is about increasing the efficiency of “last mile” deliveries by moving more cargo, making more urban-delivery stops, and speeding up cargo-access time. These solutions counter the costly, less-than-efficient, outcomes of logistics decisions made about delivering an item immediately after it is sold online (as described in Part 1 of our September 2017 issue).

STRONGER LINKS

Last mile delivery is the final link in a transportation chain, moving cargo from Point A to Point B, then C, and sometimes beyond. Like the saying goes, “a chain is only as strong as its weakest link.” If any step of transporting raw materials to manufacturing/processing facilities, moving the finished goods to warehouses, or delivering them to end recipients is less-than efficient, the entire process can become so. Likewise, if a link in the chain—such as last mile delivery—is strengthened, overall improvement could be the net effect. Enter Kinedyne’s Kin-Slider 30-second curtain-side vehicle system, which is changing the equation for last mile delivery.

The Kin-Slider provides a technological advantage, resulting in speed and efficiency for fleets with chassis-mounted truck bodies using rear- or side-mounted roll-up doors, or traditional curtain-walled vehicles. The Kin-Slider can be added to virtually any truck body when ordering from an OEM.

INCREASING CARGO ACCESS

“The Kin-Slider opens and closes at both ends of the truck or trailer, and cargo can be fully accessed throughout the length of the vehicle, and the curtain closes again within just 30 seconds,” says Paul Wolford, vice president of sales and marketing for Kinedyne LLC. “Side admission alone increases cargo access between 300 and 1,000% on some vehicles because it enables delivery personnel to retrieve cargo from a much-greater area and at a more-shallow depth.”

With rear-only cargo access, sequenced cargos have to be loaded with the last delivery placed in the virtually inaccessible forward position. With two-side and all-side cargo access, operators can flex to unforeseen circumstances that require a change in delivery schedules.

“Two-side and all-side cargo access also gives delivery vehicles the greater flexibility and latitude they need when making deliveries in dense urban cores, on neighborhood cul-de-sacs, and everything in between, Wolford says. “Greater cargo access means that delivery personnel can make loading and unloading decisions that are safer, more convenient, and less physically stressful.”

Kin-Slider has a full-length, vertical, multi-latch closure system, with all-in-one latch-release mechanisms forward and rear. Latches are easy to reach and operate when standing next to the vehicle.

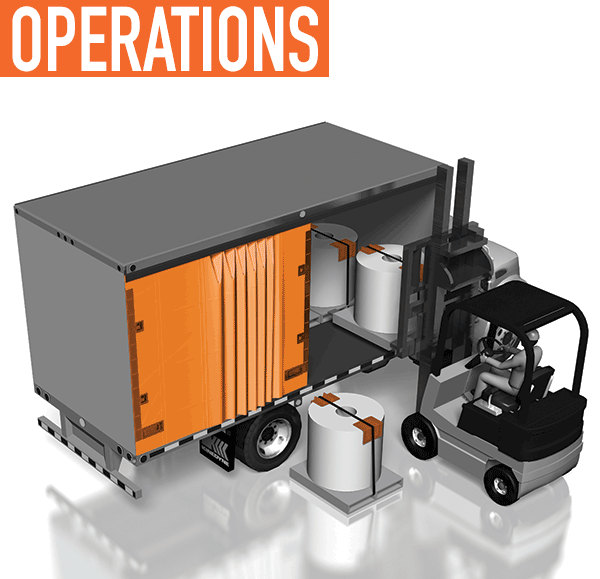

Featured Image: Side access readily provides ample space for a forklift to load and unload heavy cargo.

Above: The side opening delivers increased access to even a chock-full load of cargo.

QUICK AND ERGONOMIC

With the Kin-Slider system, a delivery operation can see results on day one. Not only is it faster for accessing cargo within a vehicle, but its effortless operation and ergonomic design mean drivers don’t have to strain to open and close roll-up doors.

“In a beverage truck application for example, the Kin-Slider system weighs up to 1,000 lbs less than a roll-up door system and requires up to 111 cubic feet less space, Wolford says. “The space saving alone is enough for two extra pallets on a 28 ft delivery vehicle, creating a 15% increase in payload capacity.”

Companies will also save on maintenance costs. Roll-up doors can deteriorate with use, are prone to damage, and are sometimes costly to maintain. The Kin-Slider system is robust, and operates virtually maintenance-free. It uses high-strength aluminum track, high-quality rubber seals, and curtain PENTA rollers made with five sealed bearings.

Kin-Slider uses digital printing with resolutions of up to 360 dots per square inch for branding parts. Printed graphic applications are covered with an anti-graffiti coating, which protects image quality and brand integrity against UV rays and fungal growth. Damaged curtains can be easily replaced.

SMART START AND FINISH

“When you’re involved in the upstream side of the supply chain and your downstream customers are coming under increased pressure to provide faster, and in many cases, free shipping, you’re going to be looking for ways to optimize your shipping operation to support them,” Wolford says.

Many fleets have started by examining the usual suspects of weight, operational efficiency, and maintenance. Kinedyne is presenting new start-to-finish solutions that address increasing pressures on transportation providers to reduce weight, optimize cargo securement, maximize cargo density, increase cargo access, and generally speed up the movement of cargo to factories, distribution hubs, and final destinations, while also reducing maintenance costs.

Moving finished goods to warehouses and customer-facing urban deployment centers is all about efficiency and cost reduction. Kinedyne has developed high-density cargo-loading solutions that maximize asset use for dry vans, reefers, and curtain-side trailers, virtually doubling capacities. The Kaptive Beam® Decking System was the first to enable a system to remain in the vehicle during loading and unloading. Kinedyne is also the first to offer a double-deck system that works with curtain-side trailers.

The same cargo-access technologies that speed deliveries in the final mile, also help transportation and logistics professionals minimize the time it takes to transition cargo from one place to another, and save significant weight in the process. Kinedyne has now introduced lightweight curtain-side and retractable roofing systems that can open and close in less-than 30 seconds. These blazing-fast cargo-access technologies can fit full-length trailers, drop-decks, pups, vehicle carriers, box trucks, glass trucks, and beverage trucks. There are even curtain-side solutions for reefer applications.

So, if a supply-chain continuum is less-than efficient, easier cargo access could be key to making improvements. Kinedyne’s technologies are aimed at providing for more time, more stops, more cargo, and more profit, up to the last mile.

FOR MORE INFORMATION:

Find out more about Kinedyne and its cargo control for commercial vehicles, visit www.kinedyne.com.

_______________________________________________________________________

MODERN WORKTRUCK SOLUTIONS: OCTOBER 2017 ISSUE

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern WorkTruck Solutions magazine.

![]()