As we enter 2025, for most in the work truck industry, gone are the days when the common failure of incandescent lights could mean citations from authorities and work stoppages in lowlight conditions. Although today’s LED vehicle lights still have a finite lifespan, it’s 50 times that of their incandescent predecessors. However, heated LED lamps pose a unique challenge, due to a common design feature that often leads to their untimely demise.

Optronics International first launched its new family of heated LED work lights and stop/turn/taillights featuring smart temperature-sensitive heating technology in December 2023. Unlike other heated LED lamps that generate constant heat whenever the light is on, potentially shortening the LEDs service life, Optronics’ TLL75 Series LED flood beam work lights and STL13 Series four-inch round LED stop/turn/taillights automatically activate heating only when temperatures drop below 50°F, when ice or snow are likely to accumulate.

This as-needed heating improves LED longevity, and enables for a full lifetime warranty on the entire lamp. For fleet operators and truck upfitters seeking to minimize vehicle downtime and maintenance costs in harsh winter conditions, the self-regulating heated LED lamps provide a dependable option backed by comprehensive protection.

SMART HEATING STARTS AT THE CORE

Many heated vehicle lamps rely on filaments embedded in the lens, similar to a rear window defroster, to melt away ice and snow. However, these exposed filaments are vulnerable to damage, allowing ice to obscure the lens if they fail. Optronics takes a different approach, initiating heating at the heart of the lamp, the circuit board.

When the built-in microprocessor detects temperatures nearing freezing, it activates internal heating elements to quickly warm the entire lamp assembly, including housing, lens, and electronics. This whole-lamp heating melts ice and snow, while safeguarding all components against damage. Environmental testing shows the TLL75 and STL13 lamps can melt five millimeters of ice in 15 minutes even after a completely cold start at -22°F.

“Unlike many other lamps that are constantly ‘cooking’ themselves to death, our heating technology only comes on when necessary,” says Dustin Smith, vice president of sales, Optronics. “Our lamps are smart, and our microprocessors are programmed to start heating only when temperatures begin dropping below 50 degrees Fahrenheit in preparation for ice and snow and as the environment warms again, they stop heating.”

HEAVY-DUTY DESIGN HANDLES HARSH CONDITIONS

The TLL75 Series work lights feature powder-coat exteriors and stainless-steel mounting hardware. A polycarbonate lens shields the LEDs, while an IP69K rating ensures reliable performance even when exposed to wet, high-pressure wash-down environments.

“Two TLL75 models provide a choice of beam patterns and intensities. The TLL75FHHB delivers a 4,500-lumen raw output in a flood pattern, with 2,800 effective lumens for piercing through snow, fog, and dust,” says Smith. “For a more targeted beam, the TLL75AHHB uses an amber lens that minimizes reflectivity in snowy conditions, producing 2,000 effective lumens from 2,300 raw lumens.”

The TLL75 and STL13 Series employ solid-state surface-mount device (SMD) construction. This technique encapsulates the LED components against moisture intrusion for superior protection compared to hollow-core lamps. Both lamps are compatible with 12- and 24-volt vehicle electrical systems.

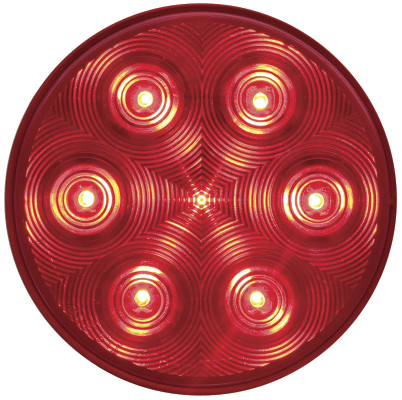

The STL13 Series four-inch round LED stop/turn/taillights provide the same microprocessor-controlled heated lens technology as the TLL75 work lamps in a compact, versatile format for a wide range of trailer and work truck body applications. Seven bright red diodes in a sonically sealed, waterproof polycarbonate lens and ABS housing deliver ample illumination and long life with grommet mounting and a standard 3-pin wiring connection.

LIFETIME WARRANTY MINIMIZES DOWNTIME

The TLL75 and STL13 Series lights are provided with a lifetime warranty. If even a single diode fails in the work lamp, flood lamp or stop/turn/tail lamp, Optronics will replace the entire lamp for free for as long as it remains in service.

“The coverage provides work truck and work trailer operators with valuable peace of mind, allowing crews to rely on Optronics heated LED lamps to keep working safely and productively in the darkest, coldest, harshest winter conditions,” says Smith. “By virtually eliminating light-related downtime, Optronics lamps help fleets and operators complete jobs on schedule, avoid late penalties and maintain hard-earned reputations.”

For truck body upfitters and trailer builders, Optronics’ lifetime LED warranty minimizes warranty claims and time spent tracking down replacement lamps.

SMART HEATING IMPROVES SAFETY AND PRODUCTIVITY

For work trucks and trailers operating in snow and ice, maintaining visibility is crucial for safe, efficient, and smooth operation. Snow-obscured brake lights and turn signals put drivers and crews at risk, while ice-covered work lamps can delay jobs and compromise productivity.

“Optronics’ intelligent heated LED lamps enhance safety in harsh winter weather conditions by automatically heating to quickly melt snow and ice before it accumulates,” says Smith. “Plow trucks and utility bucket trucks, for example, must operate day and night in blinding snow and freezing temperatures to clear roads and restore power. The TLL75 Series heated LED work lights provide ample scene lighting on the darkest winter days, helping operators avoid hazards and work more efficiently. Heated STL13 Series stop/turn/tail lamps cut through swirling snow so traffic can see workers ahead.”

Trailers also benefit from the visibility and durability of the heated LED lamps. Icy roads, corrosive de-icing chemicals and impacts from chains and debris can damage standard lights and reflectors. Heated LED lamps resist shock, vibration, and corrosion to stay lit in the worst conditions.

LIGHTING THAT WORKS HARD

With its new TLL75 and STL13 Series heated LED lamps, Optronics helps fleets and operators minimize downtime and maintenance expenses while maximizing winter workday visibility and safety.

“Optronics offers a broad array of lighting and harness options to meet demanding work truck applications and duty cycles,” says Smith. “Optronics products are helping to light the way to a more productive, profitable workday, and make quick work of winter’s worst weather.”

FOR MORE INFORMATION

To learn more about Optronics’ family of heated LED work lights and stop/turn/taillights, visit www.optronicsinc.com.