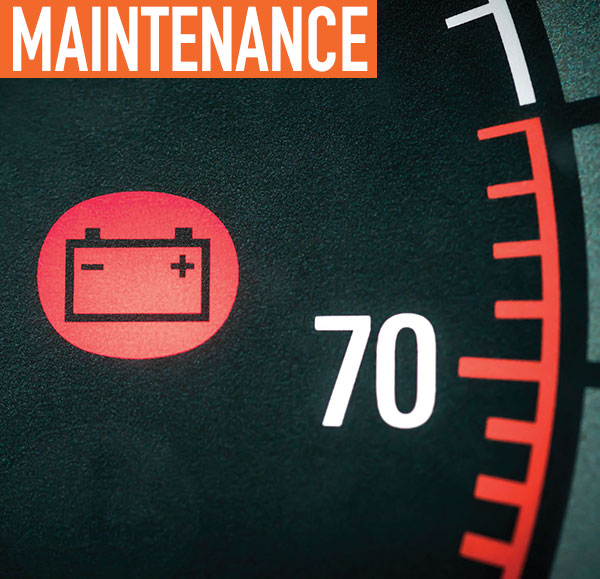

The dog days of summer are in full swing. It’s a common misconception that battery problems happen primarily in winter, but the sizzling summer heat can also have a detrimental impact on the vehicle’s battery power performance. Heat and vibration are a battery’s two worst enemies; they lead to internal breakdown and eventual failure. While drivers can’t do much about the heat, there are tips and maintenance techniques that can be easily implemented to minimize the negative effects of high summer temperatures.

ELECTROLYTE EVAPORATION

All lead acid batteries have a higher discharge rate in elevated temperatures. In conventional lead acid batteries, high heat climates can cause the electrolyte to evaporate more quickly, which shortens service life. Battery fluid evaporation can also lead to corrosion on terminals and connections. To prevent this from occurring, truck owners are encouraged to clean any corrosive buildup from the battery terminals and cable clamps and ensure the clamps are tight enough that they will not move.

Absorbed Glass Mat (AGM) batteries featuring Thin Plate Pure Lead (TPPL) technology do not have this continuous galvanic grid corrosion and as a result, have a 10- to 12-year design life. High heat has a smaller chance of deteriorating the grids when only one primary material is used: pure lead. Another benefit of AGM batteries is that the electrolyte is absorbed in a very fine fiberglass mat and the unit is sealed in the battery, which eliminates the damage that can be caused by evaporating electrolytes.

ENGINE PROBLEMS

During the summer days, heat under the hood that’s already generated from the engine is intensified by the extreme temperatures produced throughout the day. This can strain the truck battery and decrease its lifespan, making it more difficult to deliver the power to turn over the engine. But heat is not the only element that can create problems for both the engine and the battery.

The internal systems that work in conjunction with the engine of the truck can also lead to battery performance issues such as overcharging. Some of the more common culprits include the voltage regulator and the alternator, as well as the various electrical systems and accessories that pull power from the battery.

For instance, the alternator can wreak havoc on your battery if it is not building up normal resistance as it is charged. This will cause the alternator to keep charging the battery at a higher rate than normal, which can overload the charging system. An alternator that is significantly overcharging or undercharging a battery can quickly cause battery failure, according to “Cold weather actually takes a back seat to summer’s wear and tear on your battery,” by Mark Huffman in Consumer Affairs, 2014.

BRING IT TO THE EXPERTS

To ensure a battery is in proper operating condition for the hot summer, experts should conduct load testing. This is the most effective way to inspect a truck battery to know its status. It is why most vehicle service centers include battery testing and Cold Cranking Amps (CCA) ratings as part of their vehicle review processes.

For a 12-volt AGM battery, a quick assessment of how the battery is doing starts with a voltage check, which is conducted using a simple volt meter. Any 12-volt AGM battery should measure about 12.8 volts when fully charged. This varies if the truck was just running, or if it has sat with several electrical devices turned on.

When bringing your vehicle to the experts, it is recommended to test each battery separately and not in a series. Testing should be conducted when each battery is fully charged and rested for at least one hour. Most battery testers are handheld, accurate, and easy to use.

BATTERY INSPECTIONS

If opting to have the batteries inspected by a professional, here are the areas they would examine:

• checking the battery for cracks and swelling

• inspecting the cleanliness of the battery

• ensuring the terminals are cleaned and any excessive dirt removed, as it could cause electrical discharge across the terminals

• checking the connections, as they can create a barrier to carrying current while under a starting load.

SAFETY RECOMMENDATIONS

It is important to always check with the manufacturer on how to properly clean a battery. Different manufacturers recommend specific chemical cleaners that are safe to use on the plastic in their battery cases. It is also important to ensure the battery hold-down hardware is properly installed and has not loosened from the vibrations of the truck.

Warm climates increase the electric current that batteries generate, and that excessive heat can kill a battery. The rise in temperatures during the summer also increases the chemical reaction that occurs between the positive and negative electrodes and the electrolyte. In standard lead acid batteries, this reaction can cause electrolyte evaporation, but that is not a concern in sealed AGM batteries featuring TPPL technology.

Always check with your battery professional if battery maintenance questions or concerns arise. It is important to remember that high temperatures affect the life of a battery, not just its performance.

ABOUT THE AUTHOR

Alan Kohler is the marketing manager for Transporation and Specialty at EnerSys. EnerSys is a global leader in stored energy solutions for industrial applications. EnerSys manufactures and distributes reserve power and motive power batteries, battery chargers, power equipment, battery accessories, and outdoor equipment enclosure solutions to customers worldwide. Find out more, visit www.enersys.com.

MODERN WORKTRUCK SOLUTIONS:

OCTOBER 2019 ISSUE

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern WorkTruck Solutions magazine.