Last month we chatted with Jim Brodie, Reading Truck Group’s vice president of operations. He shared how Reading kept the virus at bay in all 13 of Reading’s facilities across the US while remaining open and in operation. We heard about the company’s planning, preparation, and how they learned from a false alarm. Today you’ll learn about its company changes, additional measures to address the pandemic, and how it used technology to slow the spread.

MWS: WHAT CHANGES DID READING MAKE TO SLOW THE SPREAD?

BRODIE: It shouldn’t come as a big shock that we had to make extensive changes to our physical locations and adjust workplace policies to match. That took a lot of different forms, including:

- Reducing the number of shifts from three to two

- Splitting our largest manufacturing plant into zones

- Increasing space on the line and in common areas to allow for social distancing

- Continuous education on safe behaviors like hand washing

- Providing PPE and a choice of different masks and requiring them to be worn

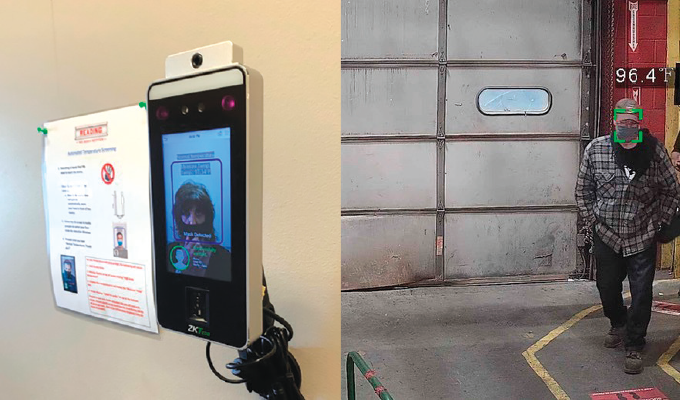

Using thermal imaging and facial recognition tools to scan temperatures and creating zones were some of the most impactful things we did. Each zone has its own entrance, bathrooms, break rooms, and other facilities. This reduces the possibility of infections spreading throughout the plant. It also lets us easily account for everyone who might be exposed if there is an infection at the plant.

Masks were an interesting opportunity to address how employees might feel amid all the changes. We provided a variety of different masks so that employees could find

the one that best fit them. It wasn’t the most important thing we did to keep employees safe, but it did let them have a little bit of choice at a time when they might have felt out of control of their routine.

MWS: HOW ELSE HAS READING ADDRESSED THE HUMAN DIMENSION TO THE PANDEMIC?

BRODIE: Clear and open communication is extremely important to ensure accurate information and help employees feel better about going to work. One of the first steps we took after forming the task force was creating a dedicated COVID-19 hotline staffed by our on-site medical team. It’s a single point of contact that employees can contact if they have COVID-like symptoms or related medical questions.

We also send text messages to employees of how many employees have contracted the virus and how many have recovered. (Only four employees have tested positive so far, and all of them contracted the virus at home from members of their household.) Keep in mind that we operated throughout allergy season and cold and flu season, so these messages calmed rumors and anxiety about employees with illnesses.

MWS: HOW CAN TECHNOLOGY AID MANUFACTURERS’ MITIGATION STRATEGIES?

BRODIE: Technology should be there to support your efforts. We use it where it makes sense to reduce friction and make compliance seamless. One example is how we use thermal scanners at our largest facility to detect employees entering the facility with elevated temperatures. Any time the cameras register a high temperature the system triggers a warning. At our smaller facilities we’re piloting facial recognition technology that will register whether an individual is wearing a mask in addition to their temperature.

MWS: WHAT OTHER ADVICE DO YOU HAVE FOR MANUFACTURING COMPANIES?

BRODIE: Of course you have to take care of the fundamentals like social distancing and hand washing. But don’t neglect how you’re treating employees. My advice is to treat them like adults. Tell them when there are risks and be open about what’s going on inside the facility.