When one particular Peterbilt 362 Cabover rolled off the assembly line in 1987, it’s doubtful that any of the factory workers imagined that it would still be in service some 35 years later. Originally outfitted with a 425-hp Caterpillar 3406B engine and a 9-speed Eaton transmission, the heavy-duty, Class 8 vehicle was much, if not exactly like many others that Peterbilt produced on that day and in that year.

The vehicle ultimately made its way to California and was upfitted with a flatbed and a crane. There, it spent its days—three and a half decades of them—moving beehives from one agricultural location to another, playing its own small role in helping to pollinate the vast array of crops the state produces virtually year-round.

During that same period, a man named James Williams and his family were busy building a business—actually three businesses to be exact. Williams Construction Company, WCC Excavation & Demolition, and J&L Contracting, a heavy-haul transportation and construction business based in Springfield, Missouri. Now doing business across the 48 continental United States, J&L’s fleet and crews are capable of moving heavy equipment and other massive loads of up to 170,000 lbs.

“Today, with our large fleet and close-knit team of fully-qualified and experienced hauling experts, we are more than capable of just about any heavy-haul job,” says Williams, J&L’s president. “Whether that be transporting huge pieces of construction equipment or moving large quantities of earth, if it’s big and it has to be moved, we move it.”

SERENDIPITY

As Williams’ companies have grown over the years, so too has his penchant for customizing the vehicles in his fleet. He has also been known to have taken on a vehicle restoration project or two in the past.

So, nobody was surprised when Williams purchased the old Peterbilt 362 Cabover and decided to restore it and to use it as a service truck to support and maintain other vehicles in his fleet. Williams drove out to California to pick up the Pete 362 and haul it back to Missouri.

While work began on the 362, Williams put an internal team together to start reimagining the Pete’s transformation to a state-of-the-art service and support truck. A friend of one of the J&L teammates was a local Caterpillar dealer. He suggested the group speak with Summit Truck Bodies to discuss the possible body configurations needed to meet the duties and functions that the group envisioned for the resurrected Peterbilt.

“We started a conversation with the folks at Summit,” says Matt Schreiner, heavy equipment mechanic for J&L Contracting. “They didn’t balk at the amount of custom work we were envisioning. In fact, they seemed ready to embrace it.”

Schreiner quickly made Dustin Sonderegger, Summit’s sales representative, part of the J&L design team, and they got to work on fleshing out all the details for the one-of-a-kind truck. Sonderegger, along with Summit Sales Engineer Brody Riddle and Summit Designer Braden Sumner, traveled to Springfield to take a good look at the ‘87 Pete. The J&L and Summit folks all started brainstorming and discussing what kind of features needed to be included in the build.

After the brainstorming, Sonderegger says “the resulting concept was probably one of the most customized service trucks out there, or that any one of us had ever seen.”

PROBLEM SOLVING

J&L had numerous parameters that the design had to support. They knew they wanted the 12,000-lb crane with longest reach Summit had available, which was 29 ft. They also had requirements for various truck-mounted equipment functions, including air compressor, power generation, welding, battery service, and hydraulics.

However, on top of the extensive laundry list of equipment that would provide the vehicle with its exceptional functionality, the team faced a major impediment. The 1987 Peterbilt 362 Cabover was never designed to be compatible with the Society of Automotive Engineers (SAE) J1939 protocol, which was only introduced 17 years later, in 2004.

SAE’s Truck and Bus Control and Communications Subcommittee developed J1939 protocol concerning the design and use of devices that transmit electronic signals and control information among vehicle components. SAE J1939 quickly became the accepted industry standard and the intra-vehicle communication network of choice for on- and off-highway machines of all types.

Without the proper J1939 interface, there was no way for all the truck-mounted equipment planned for the Peterbilt 362 to function together, nor could any of the safety features on Summit’s Advanced Safety Electronics (ASE) operating system begin to function.

Fortunately, the Summit crew had an idea. They had a close relationship with Vanair, an industry leader in mobile power solutions, and Vanair had a product that Summit thought could solve the problem.

“We ended up suggesting going with a Vanair Air N Arc I-300D,” Sonderegger says. “With the Air N Arc I-300D, not only would we have an all-in-one unit that could deliver the desired air compressor, power generation, welding, battery service, and hydraulics, but we could tie the Air N Arc’s J1939 interface into our ASE system to use the crane, outriggers, and load management safety features.”

AIR N ARC SOLUTION

Vanair’s Air N Arc I-300 was the first system in the world to offer six forms of power in a single 48-inch unit with multi-functioning capabilities. The Air N Arc I-300’s system would allow J&L’s operators to turn off the truck’s engine while still supporting the entire electrical functionality of the truck, so all the emergency lighting could still be used without fear of depleting the truck battery.

The Air N Arc I-300 would endow the antique Peterbilt 362 with an integrated 40 CFM rotary screw compressor, 7 kW AC generator, 300 AMP welder, battery booster, and battery charger, all with the added power of a hydraulic pump—and all driven by a small, 24.8-hp diesel engine. The Air N Arc I-300 offered enough power to run everything, including the proposed 29-ft crane. And the unit’s J1939 interface could connect it all, including Summit’s crane control.

“We were excited to be invited to participate in the J&L project,” says Chip Jones, strategic account manager for Vanair. “Our all-in-one unit is compact and offered six forms of power without the added bulk of six independent pieces of truck-mounted equipment. We also knew our central control system would allow users to interact with all six separate functionalities of our unit, so users wouldn’t have to climb up and down, onto, or into the vehicle to turn things on and off or to operate them—which was very convenient.”

With the addition of Vanair’s solution, the group was free to let their creative juices flow. They added a killer surround-sound system and a lighting package that could humbly be described as audacious. They planned to top it all off with a custom red paint job with accent racing stripes.

METAMORPHOSIS

As the vehicle took shape, there was no doubt that this truck was going to be something special. Its imposing dimensions alone were quite striking. They started with Summit’s Custom 20 Series body but went well beyond.

“We couldn’t stick with our standard bed height of 62 inches because we wanted to match a body line that was part of the Peterbilt’s cab design,” Schreiner reflects. “We ended up moving our bed height up to 78 inches just to follow that line.”

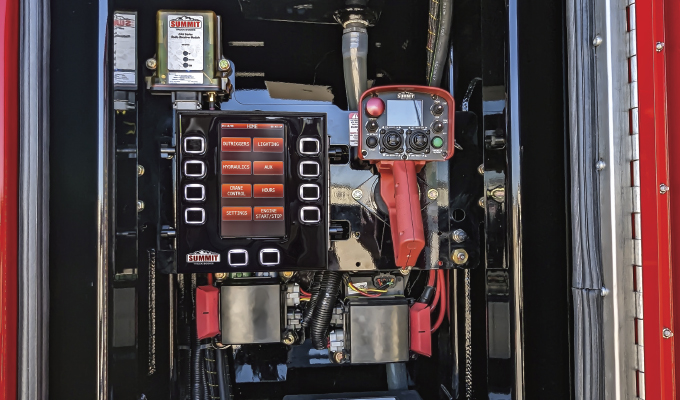

It was time to install Summit’s heavy-duty hydraulic crane and proprietary ASE system. Summit’s ASE Phase 4 operating system is essential to ensure safe crane operation and provide other innovative system functions that communicate through the J1939 CAN bus network.

Users can efficiently operate and monitor the crane, outriggers, engine, PTO, air compressor, hydraulics, and lights. Crane capacity and stability charts are programmed into the system, automatically computing the crane limits.

Based on that data and crane position, the crane will derate to maintain a safe lifting situation. As Summit’s ASE senses crane movement, its real-time load moment indicator (LMI) data will display on the main control panel, and the crane’s remote control will continuously update in real time.

When a crane load approaches its maximum capacity, the ASE will slow the crane, and the remote control’s haptic features will create a tactile, rumbling sensation, while also showing the user a notification banner. If the crane reaches its limit, it automatically stops moving, and only safe maneuvering is enabled.

The crane’s remote-control functions also include switches to start and stop the air compressor, the engine, and allow users to increase the idle. Two fully-proportional joysticks have built-in detents to guide crane controls and provide smooth operation. Users can also auto-deploy and stow outriggers with the hand-held device.

TOUR DE FORCE

Built to be noticed, the finished truck began collecting truck show awards right out of the gate. It will complete its one-year truck show tour in the Summit booth #S63207 at CONEXPO in March of 2023.

“I’m not bashful about my passion for trucks,” Williams says with a smile. “I genuinely enjoyed the restoration and rehabilitation of this Peterbilt 362 Cabover. It was truly a labor of love.”

For More Information

Find out more about Summit Truck Bodies or Vanair, visit www.summitbodies.com and www.vanair.com.