An unorganized work van can lead to lost time searching for tools and supplies, running back and forth from the worksite because tools that were thought to be in the van are nowhere to be found. Additionally, a messy van presents increased opportunities for trips and falls from wires, hoses, and other equipment strewn on the van floor. The obvious solution is to organize your work van with storage upfit solutions.

CASE STUDY

A pest control company upfitted its fleet to ensure service technicians get on and off jobsites quicker through organization and efficient equipment and tool placement. The result offers a time savings that allowed service techs to make an average of four additional service calls per week. At $80 per month, the company increased each vehicle’s revenue capacity by $16,400 annually. With 200 trucks in the fleet, the company added $3.28 million in service capacity without adding any additional employees or work vehicles. The company’s ROI was 3.4 months.

EFFICIENCY & SAFETY

For those looking to bring the same case study results to their fleet, it’s best to keep goals in mind. When modifying your work fleet with storage systems, your goals should be to increase efficiency and productivity while reducing injuries. To accomplish this, your storage system should: 1) organize and carry all the equipment, supplies, and tools needed; and 2) make them easily accessible so that injuries aren’t occurring from picking up heavy items from awkward positions or having to climb in and out of the van multiple times per day. Worker safety should not be an afterthought since preventing even one back or torn ACL claim will pay for a small fleet of storage systems.

STORAGE SOLUTIONS

Organizing your work vans is one of the best ways to increase efficiency. It is not uncommon for workers to lose hours every week dealing with a messy van. Finding the correct tools and loading materials can take much longer if your van is not orderly.

The first step is to plan and organize the layout of all the equipment, supplies, and tools you will need to carry. Identify the typical working environment that your personnel work in, and make sure any systems you are considering will work in those environments.

In addition, the van might be carrying too much inventory, or the worker may not realize they already have what they need and make the costly and unnecessary trip back to the warehouse.

FROM THE BOTTOM UP

It is best to start your organization by clearing out your van and starting fresh, then methodically finding places for everything. Whenever possible, it is best to start with placing heavy things lower to the floor. This will help prevent items from shifting. Then place lighter items on top or above the heavier items.

ORGANIZE FOR CONVENIENCE

You don’t want to just organize your items according to where they will fit, but also how often the item is used. An item used on a frequent basis should be easily accessible. Also, don’t place materials where technicians will need to step over them or where they block access to another item. Putting big items in the middle of the cargo space between side-mounted storage systems means it will have to be removed and then replaced each time you need something else stored. This significantly reduces efficiency and productivity and can also cause workplace injuries that could easily be prevented.

USE ALL YOUR SPACE

Many van solutions help organize using shelves, drawers, and storage that can be mounted along the walls of the van. As good as these systems are, they don’t maximize all the cargo space because they usually leave “dead space” in the middle of the cargo area. Often, this area ends up collecting items that must be moved multiple times throughout the day. This reduces the efficiency and productivity of your work crew.

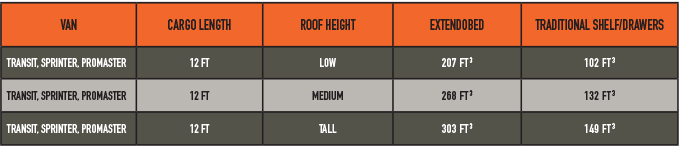

To maximize your cargo space, consider a custom-designed sliding deck-style system, which slides equipment and supplies out to the user. Extendobed offers one such solution and typically doubles the storage capacity of your van’s cargo area, while making it much easier to access (see chart on page 25).

CUSTOM SOLUTIONS

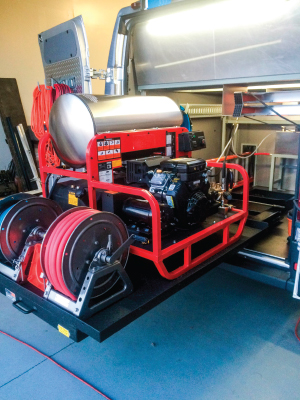

Some sliding deck systems such as Extendobed can also be customized and built specifically for your needs to include drawers, white boards, mounting walls, equipment trays, multi-tier shelving, ladder storage, tie-downs, and more.

These customized sliding deck solutions can be built in full-bed width or half-bed width designs so they can be used to slide out the side door or the back doors of a van. This allows a hybrid solution with both a sliding storage system and a traditional storage system in the van. Other simple modifications can include hooks, storage cubbies, interior ladder mounts, and lighting systems for working when dark.

A COHESIVE FLEET

Once you’ve finalized your van storage system, it is recommended to implement the same storage system across the fleet wherever possible. This ensures that any worker can be assigned to any vehicle and not lose productivity.

These are the top suggestions and options when organizing your work van. By taking these steps, you will increase the storage capacity, accessibility, and safety of your work van. Productivity and efficiency will increase, and workers comp claims should drop dramatically.

FOR MORE INFORMATION

Find out more about storage solutions for vans, visit www.extendobed.com.