Downtime due to shop delays can snowball into significant and costly productivity losses, and the time it takes to diagnose asset issues often contributes to a good chunk of that downtime. Additionally, unaddressed, or incorrectly diagnosed, issues can cause damage to other asset components. Fleets can use sensor data snapshots in fleet management software (FMS), powered by telematics, to streamline maintenance processes and keep assets running smoothly.

TRACKING DOWNTIME

For fleets, some downtime is inevitable, but unchecked downtime can have far-reaching implications. On top of the immediate productivity loss, there’s also a ripple effect on schedules, as well as customer, and employee, satisfaction, all of which can impact your bottom line.

While unscheduled downtime is often a more noticeable workflow disruption and can therefore be easier to track, benchmark, and improve, scheduled downtime is equally important to monitor. Doing so can help spotlight workflow inefficiencies, including delays due to improper staffing, unbalanced workloads, parts procurement, and time allotted to issue diagnoses.

Key metrics to track for downtime improvement planning include:

- Average percentage of downed assets in a given time period;

- Average labor hours associated with specific maintenance and repairs;

- Average lead time for parts procurement;

- Average duration of time from dropping an asset at the shop to retrieval;

- Technician productivity; and,

- High fail components and recurring issues.

Using asset service histories to estimate the amount of time specific service tasks should take can help fleets set labor hour estimates and compare expected versus actual labor hours to see instances of extended downtime due to service delays.

IMPROVING DIAGNOSES

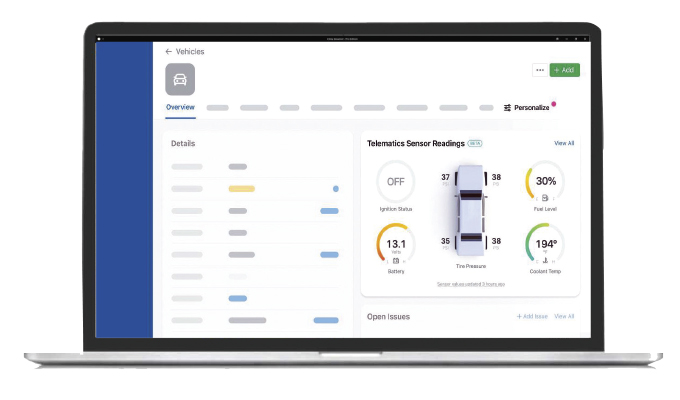

Asset fault codes aren’t always the most straightforward, as the system and component flagged may be due to an underlying issue playing a role in component failure. Using sensor data, technicians can gain access to a comprehensive view of asset issues. This allows them to identify the source of an issue with both speed and accuracy, and it provides technicians with more context so they can tackle the problem effectively.

Fleets can also use sensor data to determine if issues that happen while operators are on the road or at the jobsite need to be addressed immediately. Real-time diagnostic availability for fault alerts allows fleets to prioritize issues in a way that makes sense. If an issue doesn’t pose a safety or mechanical concern and can wait until off-hours to be addressed, it can save productivity loss.

On the other hand, if an issue arises that is more critical, fleet managers can have the operator come back to, or go to the nearest, shop. Sensor data also provides invaluable insights into soon-to-fail components so fleets can take proactive measures to prevent costly breakdowns.

SENSOR DATA SNAPSHOTS

Fleets can use sensor data in FMS to streamline service workflows, including taking a “snapshot” of selected sensor data and attaching it to new or existing issues to speed up resolution times and enhance service histories. This doesn’t just help reduce downtime in the short-term; it enables fleets to proactively address recurring issues, as well as determine whether an asset’s preventive maintenance schedule needs to be adjusted, or if the asset outright needs replacing.

Once an asset issue is raised in FMS, fleet managers are alerted in real time, kicking off the service workflow automatically. From there, managers can determine the issue’s severity and assign it a prioritization level so the issue can be addressed accordingly. Managers can then assign out a digital work order directly from the issue and attach a snapshot of the correlating sensor data. Technicians can view the sensor data, issue priority, and estimated service duration, add parts from inventory, and clock in and out of jobs, all directly within the work order.

Since extended service-related downtime can be as impactful as unscheduled downtime, it can pay dividends to track both and create a plan to address the major causes of each. Utilizing FMS’s automated service workflow functionality in conjunction with sensor data snapshots enables fleets to take proactive measures to reduce downtime and improve productivity in the shop and on the road.

ABOUT THE AUTHOR

Rachael Plant is a content marketing specialist for Fleetio, a fleet management software company that helps organizations track, analyze, and improve their fleet operations. To learn more, visit www.fleetio.com.