When it comes to commercial vehicle lighting, the word uninspired might spring to mind.

SAME OLD, SAME OLD

Traditional four-inch round and six-inch oval stop tail turn lights have been around for a long time, and although newer LED lights have largely replaced their older incandescent predecessors, not much else has changed.

These utilitarian lights and lighting shapes continue to meet federal regulations and faithfully serve the vehicles on which they’re installed. Meanwhile, the world of lighting has been progressing at a rapid pace. Look no further than the automotive industry to see how far lighting has advanced and where it might be headed for the commercial vehicle market in the future.

“If there is one thing the automotive industry understands, it is brand differentiation,” says Dustin Smith, vice-president of sales, Optronics. “They literally build it into their vehicle models and lighting design plays a major role in making many major brands stand apart from the crowd.”

SHAPE SHIFTERS

One of the ways design engineers differentiate a vehicle is by creating novel and attention-getting shapes for vehicle lighting packages. The advent of LEDs in vehicle lighting has made the design possibilities endless.

Designers also often achieve stunning appearances by incorporating unique optical characteristics, textures, and patterns into lens construction. These signature lighting approaches don’t just compliment vehicle body styles, they become an inseparable part of the vehicle’s overall visual statement.

“While automotive-style lighting design has largely escaped the purview of commercial vehicle designers and commercial vehicle lighting manufacturers as well, some, like our company, have broken from the pack in the last few years,” says Smith.

SELLING STYLE

When considering wreckers, aesthetics might not immediately cross one’s mind, primarily due to their traditional focus on utility rather than design. Yet, historical examples repeatedly demonstrate that innovative and thoughtful industrial design can enhance almost any item, not only in terms of its appearance but also its functionality and user experience.

Founded by William G. Miller in 1990, Miller Industries is the world’s leading producer of towing and recovery equipment. They build multiple brands of equipment on multiple vehicle platforms, including everything from small wreckers to 100-ton rotators with capacities of up to 200,000 pounds.

“We’ve watched as the Class 4 and 5 cab and chassis platforms that we use have progressively advanced in both style and utility,” says William G. Miller, II, CEO, Miller Industries, and the son of its founder. “With this in mind, as we started envisioning the new generation of our Century, Vulcan, and Chevron light-duty wreckers, we aimed to blend cutting-edge style with their inherent sturdiness. Our goal was not merely aesthetic enhancement but to create a distinct identity for our wreckers, setting them apart from others in this field.”

The Miller team had been investigating the use of an all-aluminum body, complemented with robust and easily replaceable acrylonitrile butadiene styrene (ABS) panels. Utilizing ABS offered the potential to give the rear design a more integrated appearance, leading Miller to consider adopting an automotive-style lighting system.

“Our collaboration with Optronics, our main lighting supplier for nearly a decade, became even more integral after they merged with our primary harness supplier, USA Harness, in 2019, forming Optronics I USA Harness,” says Miller. “They were the obvious partner for this project, prompting us to start focused discussions about the possibilities.”

Both company’s design engineers engaged in creative and interactive discussions to identify the challenges and seek solutions. Their objectives were to not only meet the demanding requirements of the towing and recovery industry, but to enhance the visual appeal of the equipment.

The lighting system needed to be robust, highly functional, and easy to repair. An important aspect of the discussion was the consolidation of the lighting approach. This involved moving from separate three-inch by five-inch rectangular and six-inch oval lamps to a more unified, modular system, integrating functions like stop, tail, turn, and backup lights. The team also aimed to reduce the number of connection points between the lights and the main harness system, and decrease the number of holes needed in the body for individual lights.

TAKING SHAPE

Optronics I USA Harness embarked on the project and, after several innovative drafts, presented Miller with a design that ticked all the boxes. The new tail lamp featured a modular look, but with a unique twist, it consisted of several lamps within one modular unit. Each unit had a detachable lens, secured by three simple-to-remove fasteners, and housed three, four-inch round Optronics Fusion GloLight lamps.

The Fusion GloLight lamps boast a sleek, automotive-style appearance with smoothly glowing outer rings and sharp, central pinpoint LEDs. These lamps were a smart selection due to their integrated stop, tail, turn, and backup functions in a compact design. Having been in use for some time, the individual Fusion GloLight components required minimal adjustments and were straightforward to maintain and replace.

An additional feature of the lamp was the “C-channel”. This feature, an extended c-shaped section of the lens, partially encompassed the three internal four-inch round lights and utilized the GloLight technology.

The lamp was crafted to align seamlessly with the rear body’s contours and to wrap around the edge just enough to double as a side clearance marker lamp. One of the most inventive aspects of this design was an optical illusion that created a flaring effect on the left and right sides. Despite this appearance, only one lamp footprint was needed for both the left and right positions, leading to cost savings and a more streamlined production process.

“The final outcome was that the new lamp provided a combination of functions including stop, tail, turn, backup, and side clearance marker capabilities,” says Miller. “The whole lighting system could be connected to the vehicle’s electrical harness through a single Deutsch connector.”

YOUR NAME IN LIGHTS

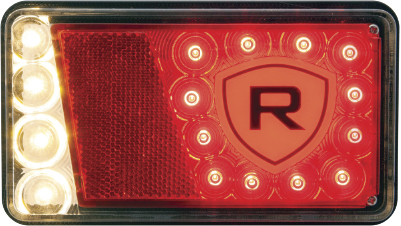

In addition to unique, custom lighting shapes, Optronics has brought automotive style to commercial lighting’s appearance. Using its GloLight technology, lighting engineers are now able to integrate intricate graphics, such as brand logos and symbols into the lamps’ functional performance. In the company’s new logo light designs, a traditional LED-style lens pattern encircles logo graphics positioned within the lens.

The new logo lights blend brand identities within their lighting design, contrasting the appearance of the GloLight portion of a lens with the more conventional LED patterns. The GloLight logo area lights up during the normal operation of the tail lamp. Moreover, when the lamp’s turn signal or brake functions are activated, all sections of the LED lamp intensify in brightness.

“These new logo lights mark a pioneering step in our industry and a unique application of our GloLight technology,” says Smith. “Logos and branding have long been a part of conspicuity tape on commercial vehicles, so their transition into lighting is a natural progression.”

Marketing experts agree that lights are some of the most prominent features on any vehicle. “Even if it’s not at the forefront of your mind, when you’re following a commercial vehicle, especially at night, its taillights are something you’re always keeping an eye on,” said Smith.

To prepare prototypes for manufacturers, Optronics utilizes its 3-D printing technology. The company has also collaborated with various OEMs during the lamp’s development, including Miller Industries.

“Our vehicles are recognized around the globe,” says Miller. “With the development of its new custom logo stop, tail, turn lamps, Optronics has presented us with another opportunity to further our brand’s recognition and strength.”

LED lamps provide a wide range of creative design options for individuals in charge of a company’s branding. This is because GloLight technology can be utilized in red, white, or a mix of both colors. Additionally, lens striations can be employed to create distinctive and visually appealing effects.

Optronics has worked with a growing variety of companies, now incorporating unique lighting shapes, combined with its logo light technology to create attention-getting lighting effects that also signify a vehicle’s brand alignment.

“Commercial vehicle lighting isn’t the most responsive to trends, especially when it comes to aesthetics,” says Smith. “However, there was a practical business case for LEDs replacing incandescent bulbs, and the same goes for smart, marketing-oriented OEMs and upfitters replacing ordinary lighting with extraordinary new branded logo lights and unique shapes.”

FOR MORE INFORMATION

To learn more about Optronics’ custom and logo lighting, visit www.optronicsinc.com.