LSI Chemical introduced two new gasoline additives: BoostPower247C and BoostPower247K. LSI Chemical engineered both to clean deposits from fuel injectors as well as intake valves of port fuel injected engines. They also clean the combustion chambers of direct injected gasoline engines.

BoostClean247C is a concentrated detergent cleaner that will effectively clean deposits with only one fill-up. With harmful deposits eliminated, users experience improved drivability, restored fuel economy and power, and a measurable reduction of exhaust emissions. The standard and recommended dosage is 2500 ppm wt/wt.

BoostPower247K is formulated to be a maintenance detergent cleaner additive to keep the engine clean and prevent buildup daily. Though less effective than BoostPower247C, it is markedly less expensive and requires only 250 lbs of additive per thousand barrels of gasoline instead of 2500 to arrive at 11 oz per 20 gal of fuel detergent. M111 results show that after a 60-hour test using E5 fuel treated with 283 mg/kg of BoostPower247K, there was a remarkable 61.3% clean-up of intake valve deposits. Both BoostPower247C and 247K works with any gasoline or gasoline/ethanol fuel mixture including E5, E15, and E85 Flex Fuel.

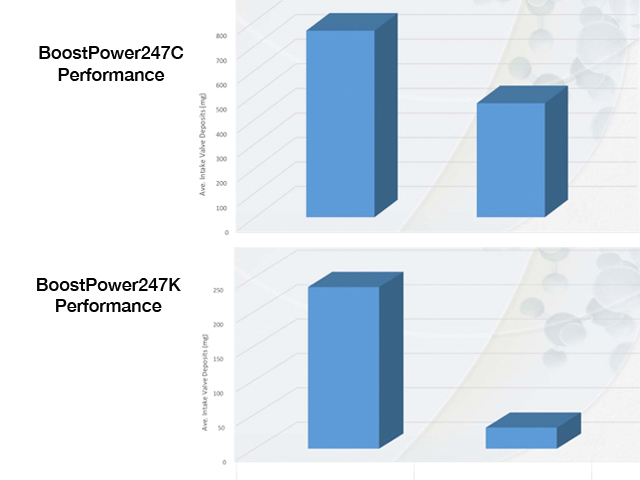

LSI TESTING

Top Graph: This shows the result from an ASTM D5500 Drive Cycle test with a 1.8-L 2014 Toyota Corolla. The purpose was to show removal of harmful deposits from the intake valves. The first bar graph shows 760 (no additive). However, the second shows a reduction to 465.1 after 500 miles using one tank of 11 oz per 20 gallons.

Lower Graph: The 247K test was performed per ASTM D6201 Dynamometer Cycle for 100 hours. The test featured a 1994 Ford 2.3-L 4-cylinder vehicle using E10 Base Fuel. The first base line bar shows 235.25 whereas using BoostPower247K @180 ppm showed a reduction to 30.75 in deposition. That’s a 96.9% reduction in deposits to the intake valves.

Find out more, visit www.lsichemical.com.