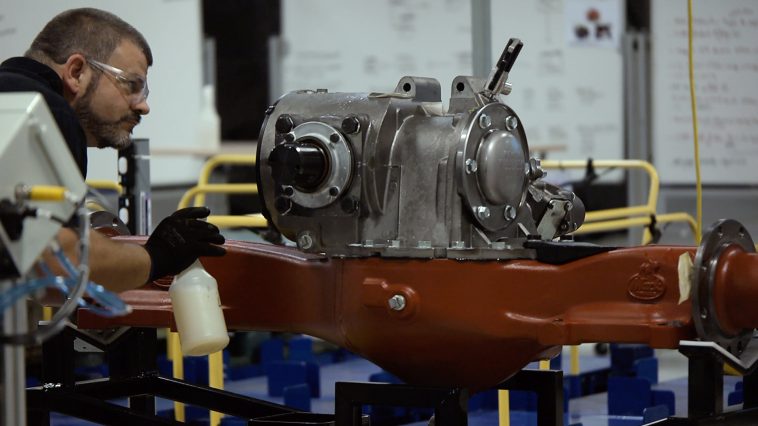

Mack Trucks introduced the Mack® S852, an 85,000-lb GAW (gross axle weight) rating of its proprietary tandem drive axles. This comes just as the brand celebrates 120 years of drive axle design, engineering, and manufacturing.

“Mack has a long and rich history of engineering and manufacturing its own powertrain components, including drive axles, as it fits with our philosophy that components designed to work together, simply work better,” Roy Horton, Mack Trucks director of product strategy, says. “We welcome the new S852, which will broaden the applications our trucks are built to handle.”

Customers in Mack’s export markets expressed a strong interest in the new rating, where local applications require a heavier-duty axle. Customers in North America will also be able to spec the 85,000-lb rated axle for specialized severe-duty or heavy-haul applications on Mack Granite models. For extreme loads at slow speeds, the S852 tandem drive axles have a creep rating of 105,000 lbs.

MACK AXLE HISTORY

The very first Mack drive axles were found on the original Mack bus model built by the Mack Brothers Company in 1900 that transported sightseers through Prospect Park in Brooklyn. After operating in Prospect Park for eight years, the bus was converted into a truck and continued operating until 1923, accumulating more than one million miles.

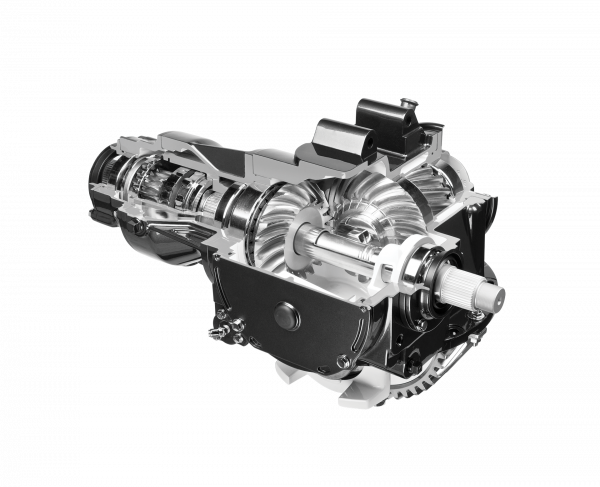

Later in 1920, a major advancement in Mack axle design occurred with the introduction of double-reduction architecture. This design reduces the speed from the drive shaft before transmitting torque to the axle shaft, as well as helps spread and balance loading over two gear sets. This maximizes axle durability.

MACK AXLES TODAY

Mack engineers today’s modern proprietary drive axles with a double-reduction design. Mack’s continuous research and development efforts were the force behind these design advantages.

For instance, Durapoid bevel and helical gears provide favorable gear tooth geometry that help eliminate localized stress and loading on the gear tooth end, providing enhanced strength and longer gear life. This gear design reduces frictional losses, allowing Mack axles to deliver up to 1.5% improved fuel efficiency.

“Low-traction situations can be a challenge for truck drivers, seriously impacting their productivity,” Horton says. “To help address that issue, we offer standard inter-axle and optional inter-wheel power dividers that automatically distribute torque between the slipping and non-slipping axle or wheel respectively.”

Mack proprietary axles also feature a top-mounted carrier design that is not only less prone to main seal leaks but also provides more than two inches of additional ground clearance. This gives customers improved maneuverability at construction sites and other off-highway applications.

An additional benefit, Mack’s top-mounted carrier design improves driveline angles between the drive axles. Instead of a 3 1/2 to eight-degree angle, Mack’s prop shaft angle is just one to two degrees. This maximizes universal joint life, allows for greater axle articulation, and reduces vibrations for a smoother ride. It also reduces torque losses for improved efficiency.

All Mack proprietary drive axles are available on Mack Anthem®, Pinnacle™, Granite®, TerraPro™, and LR models in a wide range of weight ratings. Mack axles also pair well with Mack’s suspension options, including Mack Twin-Y, Mack mRIDE™, and the legendary Mack Camelback for vocational applications.

The Mack S852 is available for order now.

Find out more, visit www.macktrucks.com.

Photos courtesy of Mack Trucks