Optronics International, a leading manufacturer and supplier of heavy-duty LED vehicle lighting, announced that it will unveil its new LED-based Purilite Light-Shield decontaminating light for the first time in booth #2534 at the 2019 NTEA Work Truck Show in Indianapolis, Indiana. The LED technology promises to bring a revolutionary level of hygiene to vehicles everywhere while improving air quality and enhancing worker safety in the process.

Many who work in, on, and around vehicles are exposed to microscopic airborne pollutants so small that they evade the body’s natural defense mechanisms, penetrating deep into respiratory and circulatory systems, causing damage to lungs, hearts, and brains. The United States Environmental Protection Agency (EPA), has developed ambient air quality trends for particle pollution, also called Particulate Matter (PM).

PM2.5 describes fine inhalable solid particles and liquid droplets with diameters that are generally 2.5 micrometers and smaller. These particles include many types of mold and bacteria found in vehicles transporting food. PM2.5 also includes soot emitted by diesel engines and APUs.

“Airborne and surface-based mold and bacteria are also a concern for those workers on vehicles that are exposed to biological residue and other contaminants,” Brett Johnson, president and CEO of Optronics International, says. “Sleeper cabs, vehicles with multiple users, and dry bulk and refrigerated food transportation haulers may be at greater risk of exposure. The climate a vehicle operates in may also be a factor in allergen and pathogen proliferation.”

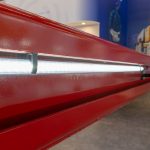

Purilite Light-Shield LED lamps generate a constant stream of negative ions, created by a proprietary coating applied to their LEDs. The lamp provides decontamination and sanitization functions while producing optimal light quality for human vision, approaching the color temperature of natural sunlight.

The ionic sanitization occurs through both physical and biological mechanisms. The negative ions bind to lightweight airborne PM2.5 particles, adding mass and enabling natural gravitational forces to remove them from the air by causing them to float safely to the ground.

The negative ions also combine with positive molecules in mold spores and bacterial proteins, destroying them and causing them to decompose. Once terminated, what’s left of the pathogens also fall inertly to the ground. With viability removed, the biological remnants are rendered essentially sterile, reducing exposure risks even if they are disturbed and become airborne again.

“When the lights are on, they are doing their job, it’s deceptively simple,” Johnson says. “A sleeper cab driver can flip on these lights, go grab a bite, and when they return, the cab environment will be significantly cleaner. If they prefer, drivers can remain in the cab while the lights are working, it’s perfectly safe just to leave them on.”

Preliminary tests in a controlled environment show a 77% reduction in PM2.5 and a 65% reduction in Escherichia coli (E. coli) in just one hour. Testing also compared Purilite Light-Shield with standard LEDs as well as no light source.

The new lamp will also help food supply chain and cold chain shipping companies comply with the most recent Food and Drug Administration (FDA), Food Safety Modernization Act (FSMA) rule on Sanitary Transportation of Human and Animal Food. With some exceptions, the final rule applies to shippers, receivers, loaders, and carriers that transport food in the United States by motor or rail vehicle, whether the food is offered for or enters interstate commerce.

“Until today, surface cleaning procedures and bacteria-resistant surface treatments were the only methods available to fleets required to adhere to FSMA guidelines,” Johnson says. “Optronics’ Purilite Light-Shield is the first technology to transcend simple surface-oriented decontamination methods and move toward cleansing the entire interior environment of a vehicle, including the air.”

Find out more, visit www.optronicsinc.com.