According to a Federal Motor Carrier Safety Administration (FMCSA) study, the use of tire pressure monitoring systems (TPMS) or automatic tire inflation systems (ATIS) can improve fuel economy by approximately 1.4%.

Fuel savings is not the only benefit here. Arguably, the number two operator or fleet cost behind fuel is tires; therefore maintaining tires properly can offer savings two-fold.

Let’s consider the benefits of proper inflation. Underinflation is always the leading cause of tires not reaching their full potential in terms of life and fuel economy. Along with the fuel savings, by always maintaining proper cold tire pressure, operators and fleets can extend tire life by 10%. This is especially important in the case of those who use retreads. According to TRIB (Tire Research & Repair Information Bureau), proper inflation and following Industry Recommended Practices (IRPs) maintains casing integrity through the life of the tire, which can be two or three retread cycles. According to TRIB, it takes approximately 22 gallons of oil to manufacture one new heavy-duty tire. Since most of that oil is used in the tire casing, which is reused in the retreading process, only 7 gallons of oil is required to retread that same tire. This means each time a tire is retreaded, approximately 15 gallons of oil are saved, adding up to millions of gallons of oil saved every year.

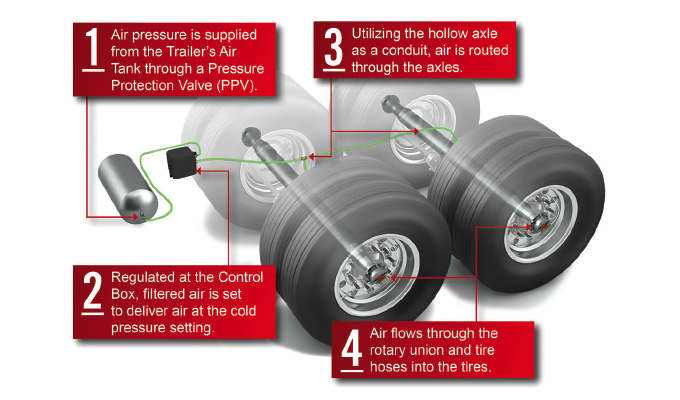

INFLATION SYSTEM

Having the proper systems in place can help operators reduce the risk of tire-related issues and increase fuel economy. One solution is an automatic tire inflation system. For heavy duty trailers, ATIS maintains your recommended cold tire pressure automatically, using the air brake tank to air up your tires (don’t worry, a pressure protection valve ensures the brakes have priority over tires). While a pre-trip inspection can be effective to verify proper inflation at the beginning of the trip, the driver does not have tire visibility after the vehicle leaves the terminal.

In the case of a slow leak or puncture while driving, the tires are maintained without the need for operator intervention. The loss of fuel economy, increased tread wear, and the potential of a roadside call is avoided during the time the trailer is run until the tire can be repaired.

As mentioned earlier, underinflated tires increase fuel consumption. It is a common statistic that 10% underinflation causes a 1% degradation in fuel economy. Numerous studies have also found a significant percentage of tires are underinflated. An FMCSA 2007 study found that only 44% of tires were within 5 psi of their target pressure. This is especially important when considering that low rolling resistance tires are the norm. Don’t expect to see the “as advertised” performance if tires are run underinflated.

COMMON MISTAKES

Another thing to consider is that many fleets don’t follow the tire manufacturers’ load tables. Some operators use the maximum pressure listed on the sidewall. The recommended practice is to determine the maximum load on the tires, then refer to the load tables to determine their cold pressure. Some fleets do this because it is “simpler” to manage a single tire pressure across all wheel positions. It should be noted that when using ATIS on trailers, this argument becomes null and void.

Another common mistake is using pressure gauges that are not calibrated. On average, some “Out-of-the-Box” slide-style pressure gauges will typically be +/- 2.5 psi, and the accuracy decreases with time and use. This is especially true if the gauge is dropped or damaged.

Even worse, some drivers will use a “tire-thumper” or walk around and kick the tires, listening for a certain sound to tell them that the tire is low on air or if it’s OK to hit the road. A Commercial Vehicle Safety Alliance (CVSA) study found that the sound of a tire does not change until it reaches 40 to 50% of its recommended pressure, which is technically flat.

USING AN ATIS

When implementing an automatic tire inflation system for their air brake equipped trailers, operators specify the recommended cold tire pressure setting to the ATIS manufacturer, which is preset at the factory. After installation the operator must remember to have new tires inflated to approximately 5 to 10 psi below the system cold pressure. After installation, they should let the ATIS bring the tire up to the recommended cold tire inflation setting of the control box. If specifications change, the ATIS control box can be adjusted to the new settings.

As part of a commercial vehicle maintenance, ATIS does require periodic inspection and potential adjustments or replacement parts to keep them in the proper operating condition. However, the savings provided far exceed the relatively low cost of maintenance. At a very basic level, a visual inspection of the tire hoses and control box should be part of every pre-trip. Ensure that the input to the control box is in the “on” position. It is also good to manually check the tire pressure a couple times each year. Some systems offer tire hoses with auxiliary ports that allow for faster pressure checks. At least annually, fleets should check the output pressure from the control box.

As you can see, proper tire maintenance is important for many reasons, with fuel economy improvement leading the cause. Because of this, ATIS can offer a return on investment in as little as a year. Further, with most systems having the ability to operate without any serious maintenance for many years, it’s a no-brainer addition to any heavy-duty trailer.

FOR MORE INFORMATION

Pressure Systems International (P.S.I.®) is a leader in onboard tire management systems for commercial vehicles. P.S.I.’s portfolio includes automatic tire inflation systems (ATIS) for commercial trailers, tire pressure monitoring systems (TPMS), and related TPMS telematics products. For more, visit www.psitireinflation.com.