The work truck industry hasn’t always been known to be the fastest to adapt to new technology. These issues arise between the sheer size of the trucks and complexities in different systems. Being a technician five to 10 years ago wasn’t easy, and when add new technologies, it makes it much more difficult.

Power Take Off (PTOs) are still a gearbox, and they still bolt up to the transmission, yet integration, wiring, and the software communication is very different today. The once straightforward task of bolting on the PTO, checking for backlash, and connecting two wires has been left in the dust, leaving a more complex process leading us forward into the future.

Ensuring safety during PTO installation is vital. Prioritizing the well-being of yourself and your staff can prevent extended absences of key individuals due to injuries, which are crucial for the smooth operation of the company. Without proper tools you will not be able to interface with your truck settings.

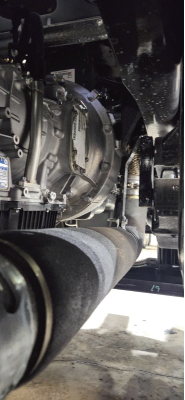

Configuration can be a crucial factor when installing a PTO since trucks now have less space underneath them. It is very important to have a game plan before setting up the PTO, so you do not run into issues with fitting the PTO and not having the proper features in the truck to allow for a quick setup.

ISSUES TECHNICIANS FACE

A few weeks ago, a team of engineers, seasoned mechanics, and truck technicians installed a new PTO on a new 2025 Class 7 truck. During that installation the reality of integration came to life. The reality of advancements in technology are outpacing the technician and challenging the current work force.

Safety First

- Follow your company’s safety practices and procedures.

- Do not get under the truck if it is running.

- Remove the keys from the ignition and store them in a safe place.

- Read and understand the installation documents and warning decal or precautions before starting any work.

CHALLENGES IN SOFTWARE DIAGNOSTIC TOOLS

The vehicle was ordered with a factory installed prep package, The new truck was equipped with a diesel engine and a new automatic transmission. The transmission has two eight-bolt apertures for mounting the PTO at either three or nine o’clock. The new PTO was a hydraulic clutch shift series for an outdoor sign company application. What they found: If you do not have the knowledge, and tools to “talk to the software” you can be in for long days of troubleshooting.

Without the right expertise and tools, troubleshooting software can lead to frustrating long shifts.

TOOLS TO MAKE THE JOB EASIER

Today’s trucks are different. They are lighter, more compact, more computerized, and technologically advanced. Historically manual transmissions were the norm. Now automatic transmissions are standard. Where bulky heavy mechanical parts were the norm, now lighter compact sensors providing signals communicating back and forth with the transmission, engine, and cab software controls are. Everything works in concert, electrically.

Performance information and fault data are recorded and searchable for easy access just by plugging in. Diagnostic tools are required to plug into the system to retrieve key information. Tools, without which, make it virtually impossible to interface, modify and control parameters on the truck. Hence, plugging in allows access to parameter settings such as engine rpm and PTO mode, overspeed protection to creep mode feature to name a few.

One of the significant challenges we face is the use of software diagnostic tools. These tools are essential as they enable clear, two-way communication between the truck’s software and the technician, ensuring accurate diagnostics and efficient problem-solving. Most larger shops have them, but fleets and small shops might not. A voltmeter is useful but will not be very helpful when communicating with the truck.

THINGS TO KEEP IN MIND

The challenge is reading up on and getting OEM training to better comprehend the truck’s J1939 communication system, essential component software and OEM wiring diagrams. The importance of understanding the software features, diagnostic abilities and electrical components of a new truck cannot be overstated.

Tighter truck spaces make PTO installations more challenging.

THINGS TO THINK ABOUT BEFORE INSTALLING THE PTO SYSTEM

- Did the truck arrive as ordered?

- Will it be appropriate for the end-user?

- Does the truck have the expected PTO package features?

- Is the truck set up both electronically in the cab and mechanically configured under the truck and between the frame rails to facilitate the PTO, pump, and hydraulic system for the application?

- If you run into an issue where installation is not achievable on the driver side, then the passenger side has space to do the installation of the PTO.

KEYS TO SUCCESS

First and foremost, work with suppliers who provide field service help after the sale. Whether the product is a PTO, transmission, or a truck. Purchase from a company who stands behind their product and has the people in place to help when needed. They have the tools and can troubleshoot your situation. Work hand in hand with suppliers so you can be better prepared next time.

Team up with skilled technicians who are problem solvers. If you are in the business of upfitting trucks your mechanics and technicians must be trained and trained often. Take advantage of these supplier perks when offered by your PTO or Transmission rep.

Use the OEM’s websites. Good OEMs have body build sites and upfitter sites chalked full of great technical information. Information on wiring options, pinout details, system grounds and power sources required to achieve total and complete system communication. These websites are updated regularly and need to be consulted before each installation. Knowing these and other tips, we can work out the bugs and get out there and start building our world.

ABOUT THE AUTHORS

Katherine Osantowski is the program manager for mobile power, mobility group North America – aftermarket, Eaton. She graduated from Northwood University and holds a BBA degree in Automotive Aftermarket Management. She is responsible for the Bezares product line in US and Canada. She can be reached at katherineosantowski@eaton.com.

Mikel Janitz is an applications engineer for Bezares USA. Janitz graduated from Oklahoma State University with a BS and MS in Engineering/Management. He works in Oklahoma City, OK and covers the USA market for Bezares. He can be reached by email: m.janitz@bezares.com.