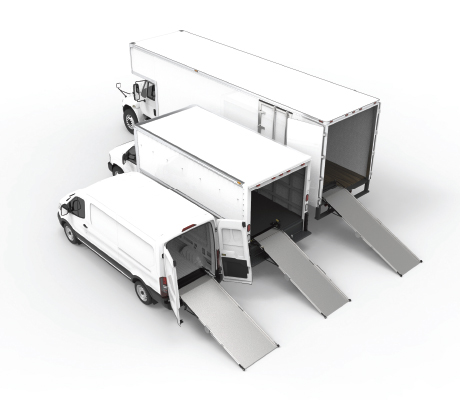

Work vans are an essential part of the commercial vehicle landscape. Vans provide an efficient and highly adaptable platform for many professions.

From plumbers to mobile x-ray technicians, vans conveniently get needed equipment to a work site. A van’s self-contained design also provides plenty of room for shelving, drawers, and other equipment storage solutions.

“Our van upfitting business really took off about 12 years ago when we started offering van shelving,” says Rob DeMars, director of operations and sales for American Bobtail, Inc. (ABI). “We’ve now grown to be one of the largest upfitters in the United States and vans represent about 80 percent of what we do.”

Based in Rockwall, Texas, the 23-year-old ABI now has 32 bays and a 10,000-square-foot warehouse on its 14-acre campus. The company specializes in light- and medium-duty commercial vans and trucks, and offers a complete line of equipment, service, and parts.

Once the van shelving segment of the business started to take off, DeMars says customers started asking about ramps and other accessories. One place DeMars always uses to find the latest innovations in van equipment is NTEA’s Work Truck Week.

“I saw the Link ramps for the first time at the NTEA show and the first thing that sold me was the spring-assist feature,” says DeMars. It made stowing and deploying ramps out of the back of a van remarkably easy and almost effortless.”

DeMars noted that hydraulic liftgates and small electric cranes can also be used for loading and unloading certain types of equipment and cargo from vans. However, they come with their own challenges, including initial expenses, ongoing maintenance, potential service interruptions, and the need for operator training.

THE ASCENT OF RAMPS

Over the years, progress in design, engineering, and material sciences have driven improvements in ramp technology. Known for its durable, low-profile swivel and folding aluminum ramps, Link Manufacturing has become a benchmark.

“All Link ramps are designed to fit neatly behind the doors of a vehicle, using less than 12 inches of horizontal space,” says Lynn Blake, national account manager for Link Ramps. “They are a far simpler alternative to liftgates and cranes, as they don’t require any training to use, allowing workers to operate them immediately after installation.”

Link ramps cater to a broad range of needs, with widths varying from 24 to 47 inches, accommodating standard hand trucks and other cargo handling equipment easily. Their bi-fold ramps range in length from 72 to 135 inches, and their extended ramp models can reach up to 119 inches, complete with an adjustable support mechanism for increased stability.

Link’s swivel ramps function like traditional folding ramps when stored at the rear. They also have the capability to swivel behind the wheel well, allowing clear access to the vehicle and providing flexibility for times when a loading ramp is not needed.

In 2021, Link expanded its range with a 42 by 108 inch ramp, adding to its nine standard ramp designs. This new model offers additional width without hindering door access when mounted to one side and stored upright.

“Link’s LB20 ramps are designed to be user-friendly, and some models are available with a built-in spring-assist feature, making the opening and closing of the ramp easy for virtually any operator.” said Blake. “Upfitters love them, because they understand that the end user will really appreciate the benefits over time.”

SPRING FEVER

ABI’s DeMars believes Link’s LB20 spring-assist is well worth the price, and he suggests his customers seriously consider including the feature in their purchases. He describes a large mobile medical service business that originally declined his recommendation to choose the spring-assist option.

“Their staff transports hospital beds and medical equipment of all kinds, and I strongly urged my customer to opt for the spring-assist version of the ramps, but because of budgetary considerations, he politely declined,” says DeMars. “The first 50 units of a very large initial installation were already in the field, when I received a call from my customer emphatically telling me that his workers had told him that I was right about the spring-assist.”

ABI ended up re-fitting all the first 50 with the spring-assist ramps. Today, ABI has done thousands of ramp upfits for the same customer all over the country, and each of them includes Link’s spring-assist option.

Kevin Mulvihill, a general manager with U.S. Upfitters, agrees that Link’s spring-assist offers a critical advantage over other available ramp solutions. The company has been selling and installing Link ramps since 2004.

“The feature we find most beneficial is Link’s spring-assist, and we like the front wheel kit as well,” says Mulvihill. “If you’re getting a long ramp, you can easily open and close it when it’s spring assisted.”

Mulvihill observes that the springs reduce worker effort and thus exposure to potential back strains and other injuries associated with repetitive lifting movements.

“This is a product line that I’m super happy with,” says Mulvihill. “They do what they do very well, and so I’m not really looking for another source.”

However, Mulvihill went on to explain that the company is always looking to bring on new lines that are within its scope, and that are of the highest quality.

“We don’t sell junk and if we bring something on and it’s not working for us or our customers, we’ll immediately move away from it,” he says.

Mulvihill also complemented Link’s customer support structure and timely response. He appreciates Link’s willingness to drop ship ramps on a just-in-time basis. “We do a lot of marketing and sales through our website and Link precisely ships ramps to meet our fluctuating demands,” he says.

CONTINUOUS IMPROVEMENT

In 2023, Link Manufacturing revamped its aluminum swivel ramp product offerings, emphasizing lighter weight and enhanced mounting options, and better bumper clearance across all their ramp models. The company also undertook an initiative to reduce weight, successfully removing about 30 pounds from the original swivel mounting plate design. This significant weight reduction was achieved by optimizing the geometry of the ramp’s base plate, specifically by removing excess material in non-critical areas like between the connection points on either side.

“Our objective was to preserve the strength and structural integrity of our swivel ramps, while simplifying their installation and usage,” says Nick VanderKooi, advanced engineer for Link Manufacturing. “The redesign also incorporated a more adaptable generic grid pattern for mounting fasteners. This offers our customers more options in terms of how and where they install the ramps.”

In the second quarter of 2024, Link plans to introduce the latest model of its popular LB20 with newly designed, pull-style, gas-spring-assist lifting mechanisms. The new LB20 ramps will each be fitted with dual gas springs and will be approximately 25 pounds lighter, meaning less lifting force will be required to open and close them. Link’s new LB20 ramps will weigh approximately 13 to 16 percent less, depending on the ramp model.

Seven of the nine LB20 models will be available with the spring-assist feature and the two smaller and lighter of the nine ramps will come without. All models will now come with Link’s wheel kit as a standard feature, which will allow the ramps to deploy and retract on a wide variety of surface angles and materials more smoothly.

The new design will also ship to customers fully assembled and attached to the LB20’s revised base plate. The new base plate has a larger mounting pattern, accommodating more mounting holes and fastener sizes, making installation easier for upfitters.

FOR MORE INFORMATION

To learn more about Link ramp products, visit www.linkramps.com.