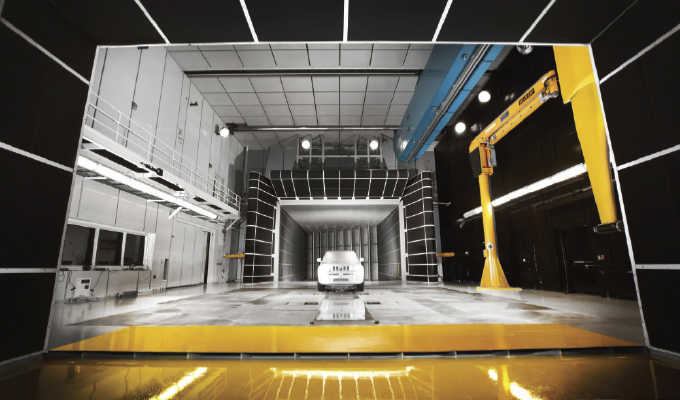

Stellantis unveiled its Moving Ground Plane (MGP) technology – a $29.5 million investment – at the company’s research and technical center in Auburn Hills, Michigan. The upgraded wind tunnel will be able to measure and reduce airflow resistance from wheels and tires, which can account for up to 10 percent of total real-world aerodynamic drag.

The upgrade to the aero-acoustic wind tunnel simulates real-world travel while allowing test vehicles to remain static. Belts suspended by cushions of air enable wheel movement at all four corners, while a fifth belt runs longitudinally beneath the vehicle, mimicking on-road travel conditions. This simulation allows for more precise testing and aerodynamic improvements. The upgraded wind tunnel also provides a valuable complement to virtual development tools.

The new facility also adds automation capability. Changes to wheelbase and track testing, which can take as much as two hours in conventional wind tunnels, can now be done in minutes. The upgraded Auburn Hills facility will be capable of accommodating larger vehicles, particularly those based on the STLA Large and STLA Frame platforms.