A major electric utility serving one of America’s largest metropolitan areas has integrated the Vanair EPEQ Mobile Support Kit into its fleet operations, using it as an emergency roadside charger (ERC) for their electric vehicle fleet. With a service territory spanning 11,000 square miles and a commitment to electrify 50 percent of its utility fleet by 2030, the company needed a solution for emergency roadside assistance that could handle unpredictable work conditions and weather events.

“The utility industry’s experience demonstrates the EPEQ Mobile Support Kit’s versatility,” says Chip Jones, national manager, Electrified Product Group for Vanair. “Their crews cover long distances daily, often responding to outages during storms. The kit ensures their evolving fleet remains operational without compromising its commitment to sustainability.”

ANATOMY OF INNOVATION

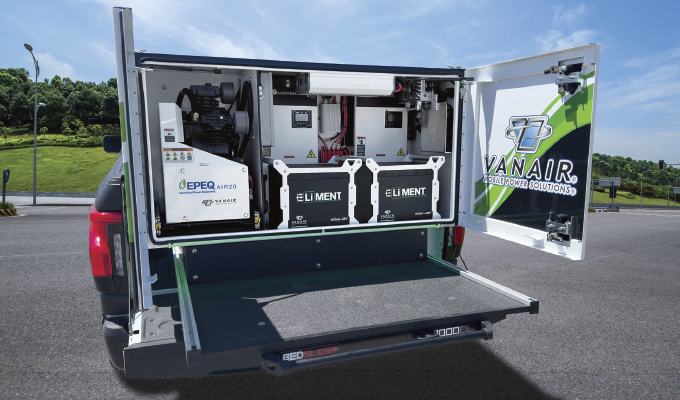

The Mobile Support Kit combines several components in a compact package measuring 60” L x 24” W x 30” H. At its core are two 48V, 100Ah lithium iron phosphate (LiFePO4) ELiMENT batteries, providing 5,000 charge cycles of power. These batteries, featuring protection against various electrical and thermal risks, serve as the foundation for the system’s multiple power outputs.

The kit’s integrated components

- An EPEQ AIR20 compressor delivering up to 20 CFM at 150 PSI;

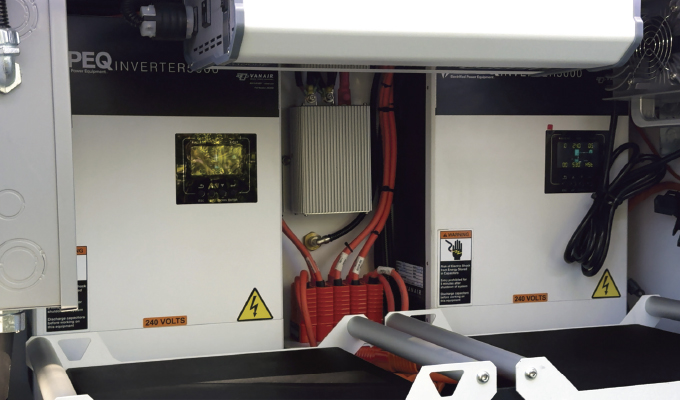

- A 3kW 120VAC inverter for standard tools and equipment;

- Two 5kW 240VAC inverters, offering a total of 10kW for higher-power applications;

- A built-in Level 2 EV charger with 9.6kW max output and 25’ charge cable; and,

- A seven-inch Smart LED Display monitoring system vitals.

APPLICATIONS

The utility company’s experience highlights the kit’s practical benefits. When an EV service vehicle’s battery runs low during extended operations, the EPEQ Mobile Support Kit can provide approximately 30 miles of range in a one-hour charge, enough to reach the nearest charging station or return to base. The kit’s portability allows it to be transferred between various vehicles, serving as both a reactive and proactive tool for fleet operations.

“What makes this solution particularly effective is its flexibility,” says Jones. “It can be loaded into any pickup truck or service vehicle, providing on-demand power wherever it’s needed. This capability is especially crucial for utilities and service fleets that can’t afford downtime.”

DESIGNED FOR THE REAL WORLD

Weighing 550 pounds, the kit is designed for installation via forklift or small crane and its plug-and-play configuration allows for quick setup. The unit recharges through a standard 120V AC outlet.

The LiFePO4 batteries offer stability compared to traditional lithium-ion batteries, with a lower risk of thermal runaway. The system’s solid-state battery management system (BMS) provides protection against electrical and thermal risks, while the IP67-rated smart display ensures reliable operation in harsh environments.

CLEAN, QUIET OPERATION

For mobile service operations, the kit offers zero emissions and reduced noise levels, it’s ideal for enclosed spaces like service vans and box trucks. This characteristic proves valuable for mobile tire services, maintenance operations and other applications requiring extended work in confined spaces.

The system can power an entire van’s worth of equipment, from tire changers and balancers to power tools and diagnostic equipment. Its dual-speed compressor offers efficient operation, with ample running times at both low and high speed, providing enough capacity for most service applications.

FUTURE-READY DESIGN

The kit represents more than just a power solution, it’s a bridge technology supporting fleets’ transition to EVs. Its ability to provide emergency charging without tapping into a vehicle’s traction battery addresses one of the primary concerns about EV adoption: range anxiety.

“Fleet operators are looking for solutions that work today while preparing them for tomorrow,” says Jones. “The EPEQ Mobile Support Kit delivers immediate benefits for both conventional and electric vehicles, while supporting their long-term sustainability goals.”

INSTALLATION FLEXIBILITY

The system’s modular design allows for various installation configurations. While it comes as a complete unit, components can be mounted individually to accommodate different vehicle layouts and operational requirements. This flexibility makes it suitable for everything from compact service vans to larger work trucks.

SUPPORT AND TRAINING

Vanair backs the EPEQ Mobile Support Kit with support, including installer training and Vanlinked QR code system, which provides users with access to training videos, manuals, and service contact information. This support infrastructure ensures that fleets can maximize the system’s capabilities while minimizing downtime.

MARKET IMPACT

As fleets face increasing pressure to reduce emissions and improve operational efficiency, solutions that bridge the gap between conventional and electric vehicles become increasingly valuable.

The utility company’s successful implementation demonstrates the system’s potential impact. By enabling their EV fleet to operate reliably across their extensive service territory, the Mobile Support Kit helps maintain operational efficiency while supporting their sustainability goals.

PRACTICAL BENEFITS FOR WORK TRUCK OPERATIONS

The features translate directly into operational advantages for work truck fleets. The system’s 20 CFM air capacity at 150 PSI, means mobile tire service operators can run their tire changing equipment efficiently. The two-speed (10CFM or 20CFM) capability allows operators to match air output to the task, conserving battery life during lighter-duty operations while delivering full power when needed.

The combination of 120VAC and 240VAC power outputs proves valuable for mobile mechanics. The 3kW, 120VAC inverter handles everyday tools and equipment, while the two 5kW, 240VAC inverters support more demanding applications up to 10kW. This means operators can run diagnostic equipment, power tools and even welding equipment without requiring separate power sources or running their truck engine.

For mobile service operations, the Kit’s Shore Power feature provides valuable flexibility. Technicians can plug into standard 120VAC outlets when available, preserving battery capacity for times when they’re working away from power sources. This hybrid approach to power management helps ensure continuous operation throughout long workdays.

The smart display system goes beyond basic monitoring, providing operators with information that helps prevent unexpected downtime. By tracking metrics like state of charge, discharge rates and temperature levels, technicians can better plan their work schedules and power usage. The system’s warning capabilities alert operators to potential issues before they become problems, helping maintain productive workflows.

The ability to mount components individually means fleets can optimize their vehicle layouts based on specific needs. For example, a mobile tire service might position the air compressor near the vehicle’s work area while placing the batteries and inverters in a separate compartment for better weight distribution and space utilization.

The kit’s emergency EV charging capability adds another layer of versatility. Beyond supporting a fleet’s own EVs, it enables service trucks to assist customers with EVs, expanding their service capabilities. The Level 2 charger’s 9.6kW output and 25-foot cable ensure practical usability in real-world situations, providing meaningful range in reasonable charging times.

Mobile service trucks can now work in parking garages, indoor loading docks and other locations where engine-driven systems would be problematic. The reduced noise level also allows for early morning or later evening operations in noise-sensitive areas, extending potential service hours.

The LiFePO4 batteries’ 5,000-cycle life expectancy translates to years of reliable service under normal usage patterns. Combined with the protection features of the battery management system, this durability helps ensure a strong return on investment for fleet operators. The ability to recharge from standard outlets also eliminates the need for specialized charging infrastructure, simplifying fleet logistics.

DRIVING FORWARD

As more fleets transition to EVs, the demand for mobile power solutions that support both conventional and electric operations will grow.

“We’re seeing interest from a wide range of industries,” says Jones. “From emergency response vehicles to mobile maintenance operations, the ability to provide reliable, clean power anywhere it’s needed is resonating with fleet operators across the board.”

For More Information

Find out more about Vanair’s EPEQ Mobile Support Kit by visiting www.vanair.com/epeq-mobile-support-kit.