As the second decade of the 21st century dawns, the commercial vehicle market is flush with enthusiasm as numerous players promise “the next big thing” in electric-powered commercial vehicles. Most of the industry’s largest truck manufacturers have or are committing significant resources to the development of vehicles with electric propulsion.

At the heart of any electric vehicle is the battery technology that is relied upon to provide energy. In some applications less energy is required to meet the demand and in others, significantly more energy is needed to displace the diesel power the industry relies upon today.

There are competing battery solutions out there, but most have one thing in common: They are not from tier-one suppliers, and the available systems rely on multiple sources for their battery, software, and thermal management components. What some have called the “reliability gap” may be causing anxiety among OEMs.

MODULAR & SCALABLE

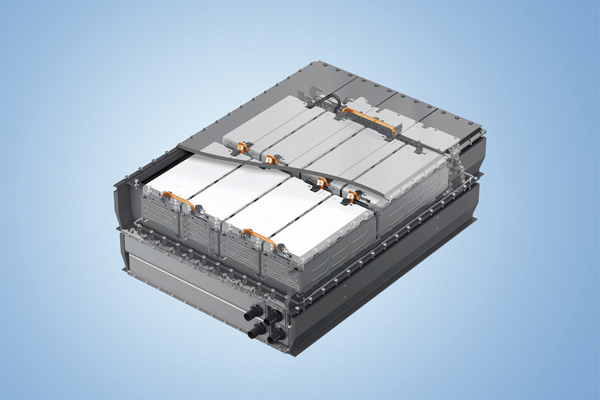

Webasto continues to stake a claim in the rapidly expanding e-mobility segment of the commercial vehicle and automotive marketplace. In November 2019, Webasto introduced its new CV Modular Battery System for commercial vehicle applications.

The Webasto CV Modular Battery System is designed for maximum scalability and broad configuration flexibility. Each battery pack has 35 kWh of energy, and up to 10 packs can be used for a combined 350 kWh.

The Webasto CV Modular Battery System is designed for maximum design scalability and each battery pack has 35 kWh of energy, and up to 10 packs can be used for a combined 350 kWh.

ACROSS ALL CLASSES

Webasto provides OEMs with a safe, reliable, single-source battery, software, and thermal management solution that is scalable. Now, manufacturers considering multiple cross-platform applications can rely on one supplier and no longer have to spend time and research and development dollars sourcing different battery systems for different vehicles.

With 400V and 800V versions available, the CV Modular Battery System can be easily configured via its vehicle interface box (VIB). The VIB is the system’s self-contained master battery management system and power distribution unit. It is truly a plug-and-play system that reduces development time and cost for the vehicle manufacturer.

“Designed exclusively for commercial van, truck, and bus applications, the footprint of the system’s VIB and modular battery packs were designed to fit within the frame rails of all major commercial vehicle makes and models,” Mark Denny, president and CEO of Webasto Customized Solutions in North America, says. Its compact, energy-dense format makes the battery packs easy for engineers to configure for use on virtually any vehicle platform, and battery modules can also be positioned outside the frame rails when necessary.

The built-in flexibility of Webasto’s CV Modular Battery System gives manufacturers of everything from light- and medium-duty work trucks to heavy-duty vocational on- and off-highway equipment to van, shuttle, school, coach, and transit buses, a practical electric battery solution.

PREDICTABILITY

Webasto can assist OEMs and fleets in vehicle specification and in the scaling of battery power and storage needs. Using sophisticated computer simulations, factors such as duty cycles, climate, and geographies can all be used to predict the appropriate number of battery packs and the type of thermal management needed to optimize battery performance and lifespan.

“One or two battery packs might be suitable for local or last mile delivery vehicle, while eight to 10 packs might be appropriate for a heavy-duty vehicle or a transit bus,” Denny says. “Depending on the use of a vehicle, many packs can be run in parallel at 400 volts and others in series at 800 volts.”

Its compact, energy-dense format makes the battery packs easy for engineers to configure for use on virtually any vehicle platform, and battery modules can also be positioned outside the frame rails when necessary.

JUST RIGHT

Conditioning the battery is essential for battery life and health. Webasto offers both off-the-shelf solutions for its CV Standard Battery and custom designs for OEM projects. Webasto’s thermal management system uses both active and passive cooling, as well as electric fluid heating and heat pump systems.

Because operating temperatures can significantly impact the operational lifespan of today’s advanced batteries. Webasto’s thermal management technology keeps the system’s batteries functioning in their optimum operating temperature range, which maximizes the life of the system. Within the battery pack, the modules also include desiccant cartridges that reduce condensation, integrated thermal runaway detection sensors, and state-of-the-art pressure equalization monitors for added safety.

“Webasto’s CV Modular Battery System is robust and designed for a lifespan of 3,000 duty cycles,” Denny says. To put that in perspective, that means that the system could be fully charged and discharged once a day for eight years.

ADVANTAGES

Electric vehicles promise to reduce the number of vehicle wear parts, decrease maintenance costs, and save fossil fuel. With Webasto’s CV Modular Battery System, OEMs will benefit from the systems modular, stackable design, allowing designers to tuck battery packs just about anywhere—across multiple vehicle platforms. Some vehicles using the system in prototype phase have been able to achieve precise overall weight balance, as well as a lower and more stable center of gravity.

FOR MORE INFORMATION

Find out more about Webasto Thermo & Comfort North America, visit www.webasto.com.

_______________________________________________

MODERN WORKTRUCK SOLUTIONS:

JANUARY 2020 ISSUE

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern WorkTruck Solutions magazine.