Until now, if you were in the market for an auxiliary, tie-in heating/cooling, or stand-alone HVAC kit for a Ford Transit, RAM ProMaster, or Mercedes Sprinter van, you’d have to first obtain a model-specific kit designed to fit your particular vehicle. However, with the popularity of vans and the variety of models out there, chances are that the kit you need might not be available when you need it.

UNBUNDLING THE PROBLEM

“Webasto has been making aftermarket van HVAC kits for years, and we alone made 22 separate systems, each designed to fit the leading van makes and models,” says Mike Cicioni, HVAC application manager, Webasto. “Our systems work seamlessly, but our distributors had to carry multiples of all 22 kits if they wanted to be stocked and ready to meet the demand.”

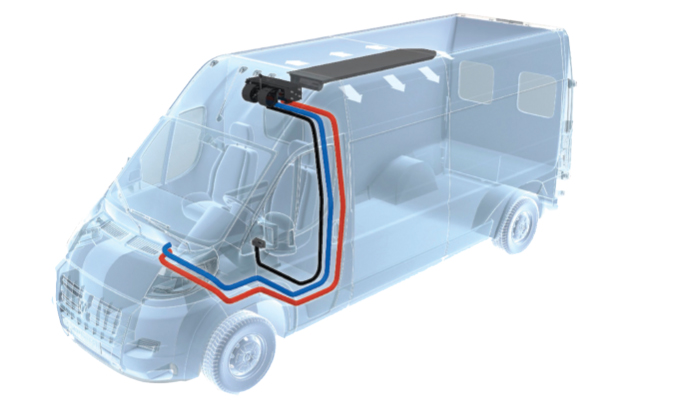

Webasto realized that many of the HVAC components they were using to make their kits were common among varying makes and models, and others were purpose designed and manufactured. They also realized that unbundling the components might make it easier for bodybuilders, upfitters, and fleets to get what they wanted with more speed and consistency.

“Our objective was to find a way to remove the burden from our customers, enabling them to carry a reduced inventory of the constituent components, instead of the potentially 22 vehicle-specific kits,” Cicioni says. “Essentially, the concept was to provide lower-cost, unbundled components that could later be re-bundled based solely on application and demand.”

It was a novel approach, and if they could make it work, they figured they could cover 90% of the van market with approximately 30 a la carte HVAC components. The approach would allow Webasto customers to carry less inventory and increase their ability to be more responsive to fluctuating demand, all while giving them the opportunity to capture a wider variety of work truck applications beyond the existing Webasto van-specific HVAC kits.

ACHIEVING INSTALL-ABILITY

Webasto engineers set out to reexamine each system and component in an effort to minimize variability and to optimize application performance. As they honed their designs, their technical teams conducted fieldwork with numerous installer groups to understand the way they would approach an installation. They took what they learned and made their designs and process even better.

“One thing I can say with great certainty, is that through their intimate hands-on work with installers, our engineering folks learned all the pain points that they needed to address,” says Matt Wheeler, head of HVAC, light and medium duty. “I know of lengthy debates over selecting exactly which was the best path to run a hose in a specific make and model and why.”

Based on their insights, the team even examined and optimized cartonning methods and physical orientation of components in their individual packaging. Installation sequences were also refined and documented in step-by-step detail so they could easily be made into instructions.

It took four years for Webasto to work through the component design and to perfect the best methods of vehicle integration. By the end, they were able to get the parts list down to between just five and seven constituent parts, depending on the make and model.

MENU-DRIVEN SOLUTION

The next step was to establish the best method for specifying the components for each vehicle. Webasto chose a decision tree method that would allow virtually anyone to choose the right system components by answering just eight questions. The questions can be answered by simply marking a brochure and noting the corresponding part numbers. An online configurator is also in the works, and it will be compatible with both desktop and mobile devices.

“This is a powerful system that is deceptively simple to use,” Wheeler says. “Now everyone can spec a system like a pro, maybe better than some.”

PROS & CONS

One of the issues that Webasto’s a la carte HVAC Kit-building System addresses is the common problem of over- or under-specifying of aftermarket HVAC systems. As in the realm of consumer HVAC system purchases, there is often confusion surrounding the correct sizing of an HVAC system required to heat or cool a specific van make and model.

“When someone doesn’t have the exact system for the job, they may suggest something they do have in stock, and that’s when the problems start,” Cicioni says. “Let’s say a van is electrically engineered to accommodate a 32,500 BTU system, but the only one available is a 40,000 BTU system. You might think, ‘sounds great, it’s really going to heat and cool my van,’ but you’re wrong. Now you’ve paid for 7,700 more BTUs, but you’re only going to get the 32,500 the system was designed to support. And the same thing goes for a system that’s too small.”

In the meantime, Cicioni insists that since the system isn’t optimized for that particular vehicle it’s going to be mechanically and electronically over- or under-performing from day one. That means the owner is likely to encounter comfort issues and service and maintenance problems down the road.

But when specified and configured using an a la carte method, a Webasto aftermarket HVAC kit will integrate seamlessly with a vehicle’s factory system. The system will provide users with optimal auxiliary heating and cooling performance because it is the right size and the right configuration for that vehicle in that application.

FINE TUNING

For large volume customers and specialty on-road vehicle manufacturers, Webasto will still provide direct support and customized application solutions. Webasto’s team of experts will deploy to a customer’s production facility and will produce a custom bill of goods as needed.

Webasto’s a la carte HVAC Kit-building System is also compatible with its Neo controller line. For AC and HVAC systems, there are four application-specific and one digital option. Each controller offers standard on/off control and variable fan speed and temperature control. Controllers are packaged in-dash or can be located anywhere inside the vehicle.

The Webasto Neo 2+ controller is an all-in-one temperature management system that allows operators to quite literally dial in the temperature they want, and the device does the rest. It’s configured with four operating modes: cooling, heating, automatic, and ventilation. It also offers an auto start-up feature that allows the system to start in the same mode and settings that were in use when the system was turned off.

The rotary dial backlights red, blue, or white, depending on the current operation mode. The OLED information screen displays set temperature, current time, and blower speed level. The system features several options including on-screen fault code display and light indicator, hour meters to assist with maintenance schedules, and Fahrenheit and Celsius preferences.

IT’S SIMPLE

Webasto’s a la carte HVAC Kit-building System is engineered to the highest international quality standards. As a tier-one automotive supplier, Webasto has built a reputation that spans more than 100 years.

“We’ve designed and engineered a system of exceptional quality that is easy to specify and install, and all at a competitive price,” Wheeler says. “In a world that seems to get more complex by the day, we just made one thing much simpler.”

FOR MORE INFORMATION

Find out more about Webasto Thermo and Comfort North America, visit www.webasto-comfort.com/en-us/.