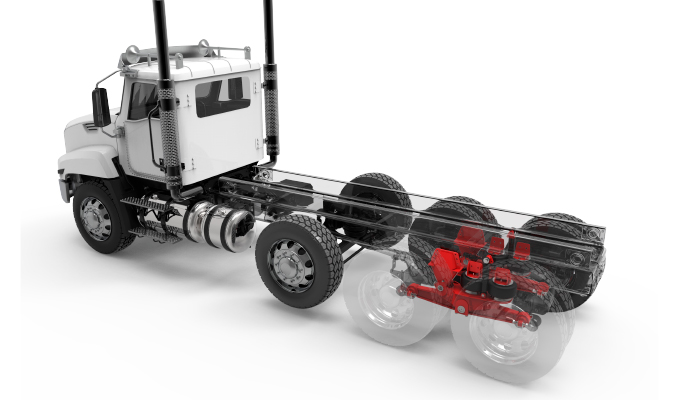

As the industry’s first, patented air-over-walking-beam suspension, the Air Link® Tandem Drive Chassis Suspension is 100% off-highway rated and can help keep vocational vehicles functioning on and off the road for more than a million miles.

TOUR OF DUTY

Link’s revolutionary Air Link Tandem Drive Chassis Suspension with its air-over-walking-beam technology was first patented close to 30 years ago. Originally designed to cope with extreme payloads and the rigors of harsh off-highway logging and oilfield applications, the Air Link’s performance characteristics were and are vastly superior to alternative heavy-duty leaf spring, rubber block walking beam, two-spring “six-rod” and trailing arm suspensions.

The Air Link comes in 85K, 65K, 52K, and 46K capacities and provides smooth, comfortable, uncompromising ride quality for operators of heavy equipment and has been compared to that of today’s advanced pickup trucks.

“The Air Link Tandem Drive Chassis Suspension was engineered to survive and thrive in extreme environments, such as Canada’s oil fields and remote northern logging areas and has also been proven in harsh military applications in the US, Canada, and the Middle East,” says Neil Mardell, senior manager of defense programs and heavy vocational products for Link. “Now optimized for heavy vocational on- and off-highway commercial applications, this is mature technology that has stood the test of time.”

THANKS A MILLION

It’s not uncommon for vocational vehicles to log a million miles or more of duty over their lifetimes. Challenging environments with rough terrain can take their toll on equipment, causing premature deterioration and both body and structural damage from exposure to high-frequency vibrations.

Air Link Suspensions deliver a smooth comfortable ride, resulting in less driver fatigue and equipment damage. High roll stability, coupled with equal weight distribution to both axles, means safer operation on-highway, off-highway, and in all weather conditions.

“Our Air Link® Suspensions make equipment far easier and more comfortable to operate and have been proven to reduce the need for body repairs on vehicles they have served,” Mardell states. “And because all Air Link Suspensions are 100% off-highway rated, users can rest assured that whichever Air Link model they have on their vehicle, it was built for the long haul, regardless of what they’re hauling and where.”

A HIGHER CALLING

As North America’s highest-capacity air spring suspension, Link’s 85K Air Link Tandem Drive Chassis Suspension is designed with large, high-volume, low-frequency air springs that enable occupants to experience a consistently smooth and comfortable ride whether their vehicle is under full load or completely empty. The suspension’s dual height-control valves ensure that proper ride height and vehicle leveling are maintained, thus maximizing roll stability regardless of the weight and balance of a vehicle’s cargo.

“Link’s 85K Air Link Tandem Drive Chassis Suspension has been optimized for select heavy vocational axles, has been engineered to seamlessly interface with tier-one online installation processes, and delivers Link’s legendary ride quality at the highest capacity for any air spring suspension on this continent,” Mardell says. “Not only is our 85K the highest-capacity tandem air spring suspension around, but because of its air-over-walking-beam design, it’s also one of the most resilient, able to continue functioning even if a loss of an air spring were to occur.”

The system’s ability to equally distribute weight, its high roll stability, and its tractive superiority make operating on challenging off-highway terrain safer, more comfortable, and ultimately more controlled. With three times more roll stability than any other vocational air-ride suspension, the Air Link rides four times smoother than a conventional spring pack and 10 times smoother than a rubber block suspension. The Air Link also offers users all the advantages of a combined air spring and walking beam suspension without all the downsides of more primitive steel or rubber walking beam suspensions.

GENERATING EXCITEMENT

Many entities with responsibilities for large-scale snow and ice management operate heavy equipment, with dump trucks and refuse vehicles often pressed into service during winter months. Unfortunately, for those fleets running 315 tires, using tire chains may cause damage to some vehicle suspensions and undercarriages due to inadequate clearance.

Link’s new 52K Air Link Gen 3 Tandem Drive Chassis Suspension is designed to meet the needs of states, municipalities, and road maintenance contractors using tire chains on heavy vocational equipment with 315 tires. The new suspension features maintenance advantages and is also lighter than previous generations of the Air Link.

Link’s new 52K Gen 3 has been reengineered specifically to improve clearance for 315 tires and chains while maintaining the exceptional ride quality long associated with its Air Link heavy vocational suspension line. Hanger brackets have been lengthened, heavy-duty dampers have been moved forward, center bushings have been raised, and the vertical distance between the trailing arm and walking beam pivots has been optimized.

“Until now, fleets managing snow and ice with heavy vocational vehicles were forced to choose between the benefits of air springs and the ability to use 315 tires,” Mardell says. “Link’s new 52K Gen 3 Tandem Drive Suspension makes their choice a lot easier moving forward.”

TRASH TALK

Refuse industry fleets were among the first to benefit from the new 52K Air Link Gen 3. Nexus Disposal of Houston, Texas, was chosen as one of the first waste management fleets to field test the Gen 3 under real world conditions.

The 52K Air Link Gen 3’s superior ride, handling, and tractive characteristics can make all the difference when a vehicle transitions from paved roads to off-highway conditions, such as transit to and from municipal dumps. These attributes also play a significant role in vehicle control when pulling off-road for waste collection. Uneven terrain and hazards such as irrigation ditches can often be encountered and may pose a potential for vehicle damage, tipping, or both.

“We really like the way the Gen 3’s dual height-control valves maintain proper ride height and leveling of a vehicle, independent of its load distribution, maximizing its roll stability,” Efrain Gonzalez, CEO of Nexus Disposal, says. “The suspension also features larger, high-volume, low-frequency air springs that deliver a smoother more even ride whether the vehicle is fully laden or empty—it really does feel like you’re driving a pickup truck.”

“We’re also happy that the Gen 3 has been engineered to enable easier service and to demand less maintenance,” Gonzalez comments, noting that the Gen 3 suspension’s anti-corrosive polyurethane bushings require no lubrication, and trailing arm bushings can be easily replaced with hanging brackets in situ.

Weighing in at only about 875 lbs, the 52K Gen 3 is not only 50 lbs lighter than other Air Link suspensions, but lighter than competing suspension offerings. The suspension has been designed with a lower number of moving parts, extra-large bearing surfaces, more brawny main components, and a higher level of load-bearing redundancy.

BUILT TO LAST

All Air Link suspensions require minimal maintenance. There are no lubrication points, and once wheel alignment is set on an Air Link, no future adjustments are required. Link recommends quarterly inspections of frame-fastening bolts and bushings as part of a preventive maintenance protocol.

All Air Link suspensions are treated with Link’s exclusive Link-KOAT® migratory self-healing metal treatment. Link-KOAT provides unparalleled corrosion resistance and rust protection even when surfaces are exposed to excessive abrasion, harsh chemicals, and other severe-duty environmental factors. All Air Link Tandem Drive Chassis Suspensions include an extended three-year warranty.

FOR MORE INFORMATION

Find out more about Link Mfg., LTD and its Air Link suspensions, visit www.linkmfg.com.